Changements technologiques et systèmes industriels, nous nous consacrons à

Fournit à Seds les meilleures solutions économiques à ses clients les plus précieux.

ZTRFM machine à couvrir les toits métalliques à joint debout, portable ou non portable, en vente

différents types de profileuses à froid. Nous sommes une usine avec une longue histoire, engagée dans la conception et la fabrication de profileuses depuis 2006. Les machines que nous pouvons produire comprennent : la machine de fabrication de tuiles, la machine de fabrication de pannes cz, la machine de fabrication de quilles en acier léger, la machine de gaufrage de métal, la machine de formage de systèmes de portes, la machine de formage de systèmes de plafonds, la machine de soudage de tuyaux à haute fréquence, la ligne de refendage, la ligne de coupe à longueur, la machine de formage de systèmes d'étagères, la machine de formage de planchers, la ligne de production de tuiles en pierre colorée, la machine de laminage à chaud filmée, etc.

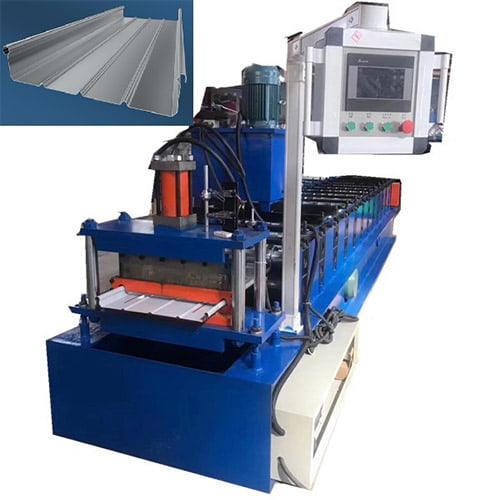

The Standing Seam Metal Roofing Machine is a versatile tool for on-site fabrication of high-quality, watertight metal roofing panels. This machine is essential for projects requiring precise, custom-length panels that can be installed seamlessly across various roof designs. In commercial settings, such as shopping centers and industrial facilities, it creates durable roofs that stand up to heavy loads and extreme weather, ensuring long-term protection and minimal maintenance.

For residential applications, the Standing Seam Metal Roofing Machine provides homeowners with a sleek, modern roofline that enhances curb appeal. The machine’s ability to produce panels with consistent seams not only looks clean but also offers superior protection against the elements. In areas prone to heavy rain or snow, the standing seam design directs water away from the building, helping to prevent leaks and prolong the life of the roof.

The archaistic tile sheet is rolled and pressed by modular glazed roll forming machine,it has many features,such as good appearance,primitive simiplicity and elegance,unique style,noblest grade,and etc. It is widely used in garden style factories,scenic resorts,pavilions,hotels,villas,exhibition halls,country clubs,and so on for outdoor decorations.

Tile roll forming machine consists of uncoiler and its base,infeed guides,fixed position driven forming stations,pressing die,shearing device,hydraulic station,PLC control console and so on.Our company has dozens of profile models for this series roll forming machine,We can design different kinds of profile and fittings for machine,as per customers’ requirement.

Please Note: All the parameters can be designed as your requirement.

Let me show you how to operate Steel Bamboo Roofing Sheets Making Machine :

Decoiling→Feeding & Guiding→Roll Forming→ Cutting→Finished Products To Support Table

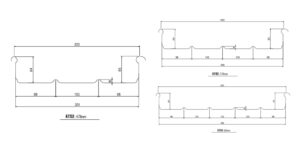

Here are some drawing profile for your reference:

Vertical locking aluminum magnesium manganese roof system product model:

YX65-300, YX65-330, YX65-400, YX65-430, etc. are used as sector plates, curved plates, and sector bent plates

Aluminum magnesium manganese vertical locking aluminum magnesium manganese board, according to design requirements, can be refined into 6 layers during system construction:

- The roof layer adopts 0.9mmYX65-430 aluminum magnesium manganese board as the panel. The panel is a layer that directly contacts the atmosphere and rainwater. The waterproof design and treatment of the opposite layer are crucial. The selection of the height and direction of the vertical edge, as well as the construction treatment of special nodes, all determine the final waterproof result.

- The insulation layer is generally made of centrifugal glass fiber sound-absorbing cotton, mainly used for insulation and noise reduction (such as the noise caused by heavy rain and hail hitting the surface layer), and its top aluminum foil has good minor auxiliary waterproof function.

Chaîne vidéo sur la machine à couture debout

Pourquoi nous choisir ?

OEM/ODM et service de personnalisation à guichet unique

Service après-vente complet

Fournir OEM、ODM

2.Conception technique : réalisation de dessins de profils et de machines en 3D

3.déterminer la configuration et la production

4.essais avant livraison

6.Conseils techniques

7.Service après-vente : services d'installation pour les machines complexes et visites régulières des clients

Plus de 95800 entreprises lui font confiance

des entreprises de haute qualité. En coopérant avec nous, elles ont reçu

Le groupe a bénéficié d'un soutien solide et a réalisé des percées et des développements commerciaux.