Changements technologiques et systèmes industriels, nous nous consacrons à

Fournit à Seds les meilleures solutions économiques à ses clients les plus précieux.

Machine à former les cadres de portes métalliques et les cadres de cloisons sèches

différents types de profileuses à froid. Nous sommes une usine avec une longue histoire, engagée dans la conception et la fabrication de profileuses depuis 2006. Les machines que nous pouvons produire comprennent : la machine de fabrication de tuiles, la machine de fabrication de pannes cz, la machine de fabrication de quilles en acier léger, la machine de gaufrage de métal, la machine de formage de systèmes de portes, la machine de formage de systèmes de plafonds, la machine de soudage de tuyaux à haute fréquence, la ligne de refendage, la ligne de coupe à longueur, la machine de formage de systèmes d'étagères, la machine de formage de planchers, la ligne de production de tuiles en pierre colorée, la machine de laminage à chaud filmée, etc.

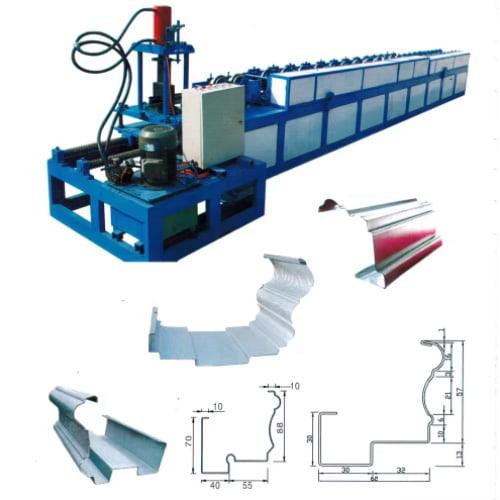

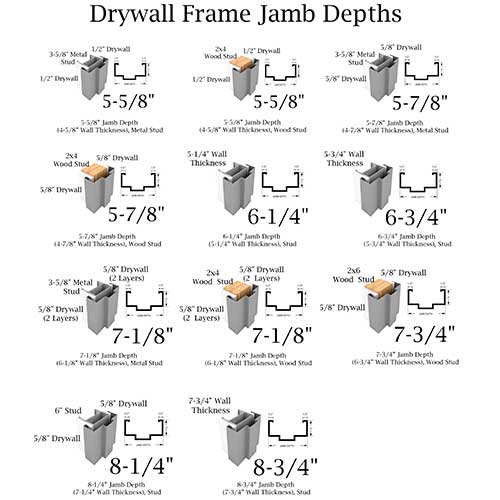

Metal door frame rolling forming machine is designed to make the metal door frame in batch fully automatically. The knocked down drywall frame is for interior stud walls and for use with steel or wood doors. Drywall frames are designed for light to heavy duty applications in both commercial and institutional buildings. Frames are installed in rough openings after the wall has been constructed and finished. They are supplied with a (knock-down) corner for quick installation. As to the metal door frame rolling forming machine we can make it either half automatic type or fully automatic type with online punching for hinges holes. Here are some standard metal door frame drawing profile for your reference:

Metal door frame rolling forming machine is designed to make the metal door frame in batch fully automatically.

Title: Metal drywall door frame rolling forming machine

Keywords: drywall door frame machine, rolling forming machine

Machine à former les cadres de portes en métal pour cloisons sèches

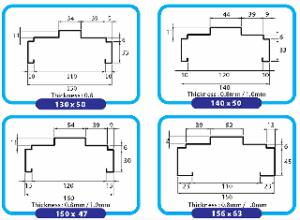

A hollow metal door frame is a type of door frame constructed from steel that has been formed into a hollow profile. This design provides structural integrity and durability while keeping the weight of the frame relatively light. Hollow metal door frames are commonly used in commercial and industrial buildings due to their strength and resistance to wear and tear. Here are some popular drawing profile for your reference:

Les huisseries en métal creux offrent plusieurs avantages, notamment:

– Strength: They are very strong and can support heavy doors.

– Fire Rating: Many hollow metal frames are fire-rated and can withstand fire for a certain period of time.

– Security: The solid construction resists forced entry.

– Durability: They are resistant to warping, cracking, and damage from environmental factors.

-Customization: Hollow metal frames can be easily modified on-site to fit various door sizes and requirements.

Based on those we make the metal door frame rolling forming machine either has the fully automatic and half automatic metal door frame rolling machine.

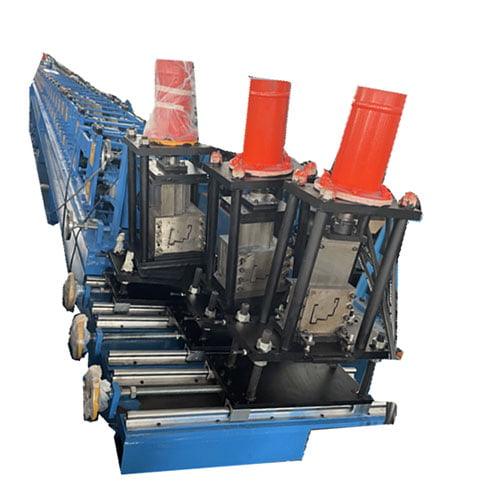

Metal door frame machine is a specialized piece of equipment used in the manufacturing process of hollow metal door frames. This machine is designed to shape or form steel strips or profiles into the desired shape of a door frame by a process called rolling.

The main features and functions of a metal door frame rolling machine may include:

- Rolling Process: The machine uses a series of rollers to bend and shape the steel strips into the U-shaped or C-shaped profile that makes up the door frame.

- Adaptability: The machine is often adjustable to accommodate different sizes and types of door frames, allowing for versatility in production.

- Automation: Modern machines can be automated to increase production efficiency and reduce labor costs. They can be programmed to produce frames of consistent size and shape.Take an example for the 45 degree shearing part, you can choose either online or offline. Also for the punching, you can also make based offline or online. For more information, you can contact me at any time.

Pourquoi nous choisir ?

OEM/ODM et service de personnalisation à guichet unique

Service après-vente complet

Fournir OEM、ODM

2.Conception technique : réalisation de dessins de profils et de machines en 3D

3.déterminer la configuration et la production

4.essais avant livraison

6.Conseils techniques

7.Service après-vente : services d'installation pour les machines complexes et visites régulières des clients

Plus de 95800 entreprises lui font confiance

des entreprises de haute qualité. En coopérant avec nous, elles ont reçu

Le groupe a bénéficié d'un soutien solide et a réalisé des percées et des développements commerciaux.