Changements technologiques et systèmes industriels, nous nous consacrons à

Fournit à Seds les meilleures solutions économiques à ses clients les plus précieux.

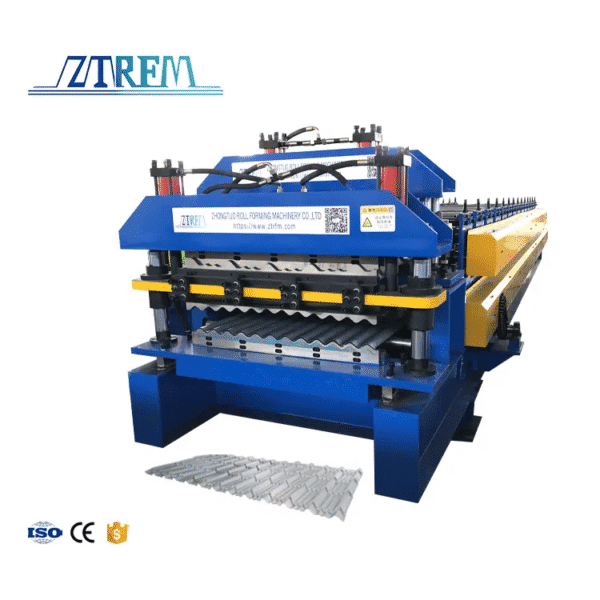

Automatic Double-layer Steel Roof Panel Roll Pressing Machine

différents types de profileuses à froid. Nous sommes une usine avec une longue histoire, engagée dans la conception et la fabrication de profileuses depuis 2006. Les machines que nous pouvons produire comprennent : la machine de fabrication de tuiles, la machine de fabrication de pannes cz, la machine de fabrication de quilles en acier léger, la machine de gaufrage de métal, la machine de formage de systèmes de portes, la machine de formage de systèmes de plafonds, la machine de soudage de tuyaux à haute fréquence, la ligne de refendage, la ligne de coupe à longueur, la machine de formage de systèmes d'étagères, la machine de formage de planchers, la ligne de production de tuiles en pierre colorée, la machine de laminage à chaud filmée, etc.

The innovative design of the double-layer steel roof sheet roll forming machine has revolutionized the limitations of traditional single-line production, making it the preferred equipment for industrial plants, warehousing and logistics centers, and residential buildings.

Precision Control System of Double Layer Molding

Our forming machine employs the core technology of ‘zoned drive + intelligent calibration’ to digitally control the entire process of converting steel strips into high-precision double-layer roof panels, ensuring both upper and lower layers meet international standards.

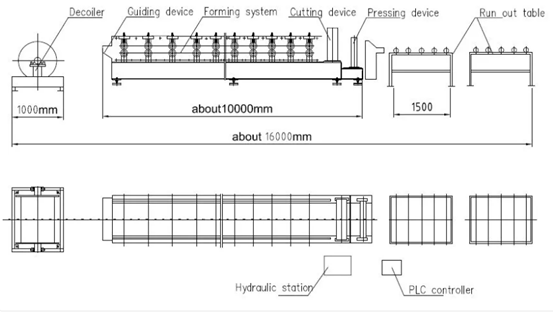

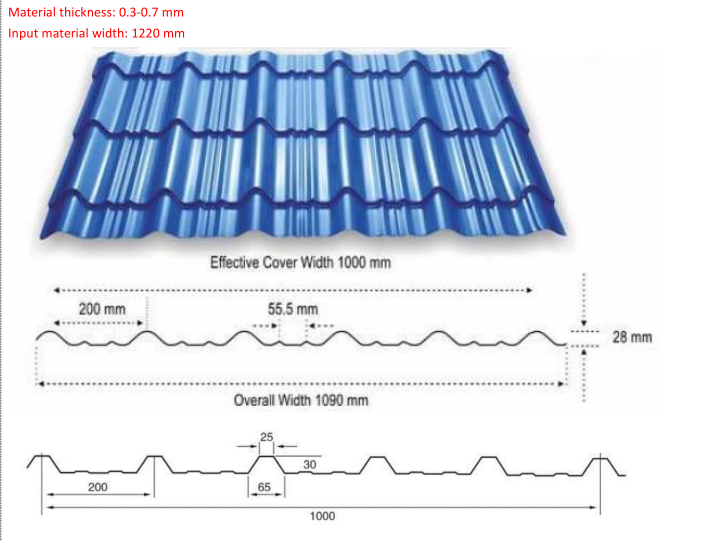

The raw material processing stage establishes dual safeguards: A 5-ton hydraulic uncoiler paired with a four-stage leveling system enables stable handling of various substrates, including color-coated steel plates, galvanized steel plates, and aluminum alloy plates, with widths ranging from 800 to 1220mm and thicknesses from 0.5 to 0.18-1.0mm. Through hydraulic tension control and laser alignment, feed deviations are maintained within ±0.05mm. The core forming stage employs a ‘dual independent roll system,’ featuring 24 corrugated plate forming rolls on the upper layer and 18 glazed tile forming rolls on the lower layer. These rolls are coated with hard chrome on 45# steel, achieving a surface roughness of Ra0.8μm to ensure scratch-free and pressure-free sheet formation.

Quality upgrade

The double-layer roof panels manufactured by our equipment achieve dual breakthroughs in mechanical performance and waterproofing. Third-party tests confirm that the corrugated panels exhibit a bending strength of 280MPa, while the glazed tiles demonstrate a flexural strength of 150MPa—both surpassing international standards by 30%. The proprietary edge-biting molding process enhances inter-panel overlap sealing by 80%, and when paired with specialized sealing strips, it achieves a water resistance of 0.3MPa, effectively resolving leakage issues common in traditional roof panels. In a Thai industrial park project, the panels produced by our equipment have been in stable service for 12 years, remaining rust-free and deformation-free despite exposure to tropical storms and intense UV radiation.

Full-scenario adaptation: from tropical typhoon zone to cold zone

To address diverse global climate and architectural requirements, our forming facility has developed a “multi-pattern, multi-material, and customized” adaptation system. The system covers 12 mainstream roofing panel types, including 840/850/900 corrugated sheets, glazed tiles, and antique-style tiles. Production can be achieved by combining any two panel types through rapid roller group replacement (type change ≤45 minutes). Material compatibility spans from standard color-coated steel sheets to 550MPa high-strength galvanized sheets, and from aluminum alloy plates to corrosion-resistant weathering steel, all achieving perfect forming through intelligent parameter adjustments.

Pourquoi nous choisir ?

OEM/ODM et service de personnalisation à guichet unique

Service après-vente complet

Fournir OEM、ODM

2.Conception technique : réalisation de dessins de profils et de machines en 3D

3.déterminer la configuration et la production

4.essais avant livraison

6.Conseils techniques

7.Service après-vente : services d'installation pour les machines complexes et visites régulières des clients

Plus de 95800 entreprises lui font confiance

des entreprises de haute qualité. En coopérant avec nous, elles ont reçu

Le groupe a bénéficié d'un soutien solide et a réalisé des percées et des développements commerciaux.