Cambios tecnológicos y sistemas industriales, nos dedicamos a

Proporciona a Seds las mejores y más económicas soluciones a sus valiosos clientes.

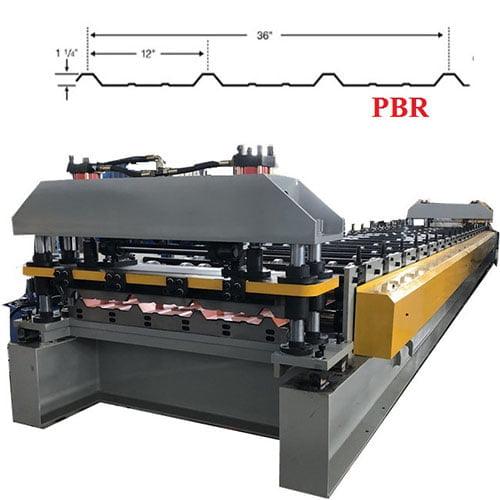

PBR panel, panel de costilla Max, Ag panel de chapa para techos de laminación que forma la máquina

diferentes tipos de maquinas perfiladoras en frio. Somos una fábrica con una larga historia, dedicada al diseño y fabricación de maquinas perfiladoras desde 2006. Las máquinas que podemos producir incluyen: máquina formadora de tejas, máquina formadora de correas cz, máquina formadora de quillas de acero ligero, máquina de estampado de metal, máquina formadora de sistemas de puertas, máquina formadora de sistemas de techos, máquina de soldadura de tuberías de alta frecuencia, línea de corte longitudinal, línea de corte a la medida, máquina formadora de sistemas de estantes, máquina formadora de cubiertas de piso, línea de producción de tejas de piedra de color, máquina laminadora en caliente, etc.

PBR panel, panel de costilla Max, Ag panel de chapa para techos de laminación que forma la máquina

El panel de PBR, el panel de la costilla de Max, la hoja del material para techos del metal del panel de Ag que forma la máquina se diseña para hacer las hojas del material para techos del metal en lote completamente automáticamente. El panel de PBR, el panel de costilla máximo, la hoja de techumbre del metal del panel de Ag son absolutamente populares en los E.E.U.U. y Suramérica. Aquí vamos a tomar los perfiles de dibujo como ejemplo para mostrar cómo nuestra máquina de láminas metálicas para techos está diseñada.

Panel Rchapa de cubierta l

R-Panel es un panel multiuso para paredes y cubiertas que se utiliza principalmente en aplicaciones de construcción metálica prediseñada. El panel R también es una opción popular para cubiertas metálicas residenciales, especialmente en el suroeste. Una pata de apoyo de correa (PBR) opcional se apoya en las correas y proporciona soporte para la fijación de la solapa del panel.

.

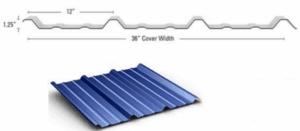

Panel Max- Rib lámina para tejados

Max: Rib es un panel de perfil bajo (3/4″) que resulta igualmente adecuado para aplicaciones de cubiertas residenciales y postes.

Las distintas aplicaciones, usos finales y expectativas requieren diferentes alternativas de paneles metálicos. Afortunadamente, Zhongtuo

El popular perfil Max-Rib está disponible en cinco opciones distintas: Max-Rib UItra, Max Rib I, Max-Rib 100 y Max-Rib

Materia prima/Liner. La mejor elección para su proyecto individual depende de factores como el rendimiento, la

longevidad y presupuesto.

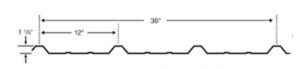

La cubierta metálica PBR perfil:

Los paneles metálicos PBR para tejados y paredes son una opción versátil y de alta calidad. Pueden instalarse fácilmente tanto en horizontal como en vertical, lo que garantiza un diseño funcional que satisface los requisitos de los proyectos de construcción de sus clientes.

PBR panel, panel de costilla Max, Ag panel de chapa para techos de laminación que forma la máquina:

| Bastidor de la máquina | Estructura de viga H de 350 mm, con placa de soporte intermedia de acero soldado de 20 mm. |

| Material de los rodillos

| Acero forjado 45# de alta calidad |

| Tratamiento cromado (grosor del cromo: 0,05 mm), hace que la superficie de los rodillos sea más lisa, mejora la dureza y evita la abrasión, anticorrosión y aumenta la vida útil. | |

| Estaciones de conformado

| Capa superior Estación de 18 rodillos |

| Tipo de laminación: concepto de diseño de laminación separado, puede liberar la tensión interna de las chapas, entonces la chapa tendrá buena forma y alta precisión. | |

| Diámetro de los ejes | Φ80mm sólido |

| Material de los ejes | Alto grado 45#, con tratamiento térmico |

| Velocidad de moldeo | 0-25 m/min |

| tensión | 380V/50HZ/3P (según pedido) |

| Vía de transmisión | Por cadena de 2,5 cm |

| Motor principal | 7,5 KW |

| Material de la cuchilla de corte | Tratamiento templado Gcr12 |

| Tipo de corte | corte hidráulico de postes |

| Método de conducción | Por tipo de pilar Cilindro |

Y si desea añadir la función de corte a la longitud, también podemos añadir para usted. El corte a la longitud podría ser junto con el PLC y ayudarle a cortar la bobina a pedazos y luego utilizar para el perfil de la tapa del canto o canalones de flexión.

Bastidor base de la máquina

1.Hay refuerzo diagonal en el bastidor base de la máquina, que puede hacer que el bastidor de la máquina más estable y más fuerte.

2.Después de la soldadura completa, se utiliza la vibración para soldar la tensión. 3.After mecanizado cepilladora a gran escala, la horizontalidad y la rigidez del bastidor están asegurados.

3.Las ruedas manuales de ambos lados se pueden utilizar para ajustar la anchura de alimentación.

4.Cuatro rodillos inoxidables pueden hacer que el material entre en la máquina suavemente y prevenir el rasguño en la superficie del material.

5.Hay tres filas de rodillos de plástico de color naranja puede hacer que la bobina de acero entrar en la máquina sin problemas.

En cuanto al desenrollador y al apilador, puede elegir el manual o el hidráulico según sus necesidades.

| Bastidor de la máquina | Estructura de viga H de 350 mm, con placa de soporte intermedia de acero soldado de 20 mm. |

| Material de los rodillos

| Acero forjado 45# de alta calidad |

| Tratamiento cromado (grosor del cromo: 0,05 mm), hace que la superficie de los rodillos sea más lisa, mejora la dureza y evita la abrasión, anticorrosión y aumenta la vida útil. | |

| Estaciones de conformado

| Capa superior Estación de 18 rodillos |

| Tipo de laminación: concepto de diseño de laminación separado, puede liberar la tensión interna de las chapas, entonces la chapa tendrá buena forma y alta precisión. | |

| Diámetro de los ejes | Φ80mm sólido |

| Material de los ejes | Alto grado 45#, con tratamiento térmico |

| Velocidad de moldeo | 0-25 m/min |

| tensión | 380V/50HZ/3P (según pedido) |

| Vía de transmisión | Por cadena de 2,5 cm |

| Motor principal | 7,5 KW |

| Material de la cuchilla de corte | Tratamiento templado Gcr12 |

| Tipo de corte | corte hidráulico de postes |

| Método de conducción | Por tipo de pilar Cilindro |

¿Por qué elegirnos?

Servicio integral OEM/ODM y personalización

Servicio posventa completo

Proporcionar OEM、ODM

2.Diseño técnico:realizar perfiles de dibujo y dibujo de máquinas en 3D

3.determinar la configuración y la producción

4.pruebas antes de la entrega

6.Orientaciones técnicas

7.Servicio posventa:Servicios de instalación de máquinas complejas y visitas periódicas al cliente

Con la confianza de más de 95800 empresas

empresas de alta calidad. A través de la cooperación con nosotros, han recibido

fuerte apoyo y logrado avances y desarrollo empresariales.