La máquina de paneles de pared exterior de metal es un equipo indispensable e importante en el campo de la construcción moderna, utilizado para producir láminas de metal adecuadas para la decoración y protección de paredes exteriores. Los paneles de pared exterior de metal producidos por ella son ampliamente utilizados en edificios residenciales, comerciales e industriales, especialmente en lugares donde se requiere durabilidad y estética. A continuación se presenta un análisis detallado desde el punto de vista de las características, ventajas y aplicaciones.

Características y ventajas de la máquina de paneles metálicos para paredes exteriores

Resistencia y durabilidad

Los paneles de pared exterior de metal están hechos de materiales fuertes, como láminas de acero galvanizado, láminas de aluminio, etc., y tienen buena resistencia mecánica. Tanto si están sometidos a fuertes vientos, lluvias torrenciales, granizo u otras influencias climáticas, los paneles metálicos para paredes exteriores muestran una gran durabilidad.

Excelente resistencia a la corrosión

Mediante tratamientos superficiales como el galvanizado, la pulverización de revestimientos o la oxidación, las chapas metálicas tienen resistencia a la oxidación y la corrosión, y pueden permanecer estables durante mucho tiempo en zonas de alta humedad o lluvia ácida.

Ricos efectos estéticos

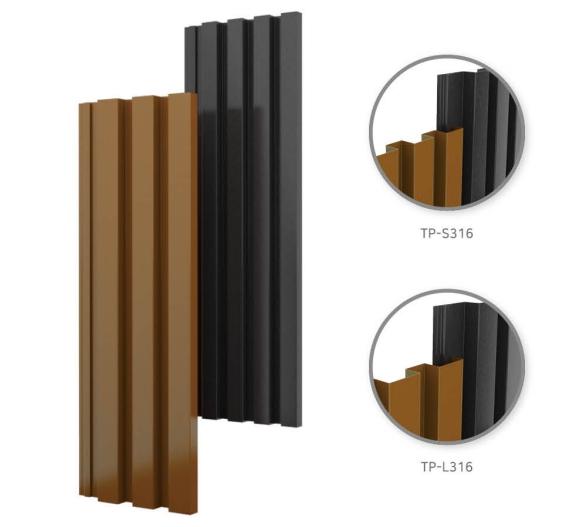

Los paneles metálicos para paredes exteriores pueden someterse a diversos tratamientos superficiales en función de los requisitos de diseño, como pulverización, laminado, glaseado, etc., lo que ofrece diversas opciones de color y textura para mejorar el aspecto del edificio.

Excelente rendimiento de aislamiento térmico

Rellenar la placa metálica con materiales de aislamiento térmico de alto rendimiento (como poliuretano, lana de roca, etc.) no sólo mejora el efecto de aislamiento térmico de la pared exterior, sino que también reduce eficazmente el consumo de energía causado por la diferencia de temperatura entre el interior y el exterior.

Fácil instalación

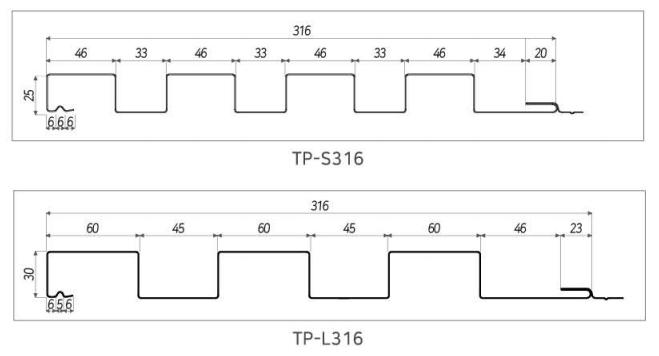

Los paneles metálicos de pared exterior adoptan un sistema de conexión de diseño modular, como el empalme empotrado o la fijación con pernos, que reduce el tiempo de instalación, disminuye la dificultad de construcción y ahorra costes de forma significativa.

Fácil mantenimiento y limpieza

La superficie de la placa metálica tiene una gran capacidad antiincrustante tras un tratamiento especial. Puede volver a estar limpia con un simple enjuague o un paño, no es fácil que se decolore o envejezca, y mantiene un buen aspecto durante mucho tiempo.

Campo de aplicación de la máquina para fabricar paneles metálicos de pared exterior

Edificios residenciales

En las residencias urbanas, los paneles metálicos de pared exterior se utilizan ampliamente como materiales decorativos, que no sólo pueden satisfacer las necesidades estéticas, sino también proporcionar buenos efectos de protección.

Edificios comerciales

En centros comerciales, edificios de oficinas, salas de exposiciones, etc., el revestimiento metálico se ha convertido en una opción popular por sus diseños modernos y diversos, que pueden personalizarse.

Plantas industriales

Las instalaciones industriales, como fábricas y almacenes, requieren paredes exteriores duraderas y fáciles de mantener, y el revestimiento metálico satisface sus necesidades y es rentable.

Edificios públicos

La durabilidad y el bajo coste de mantenimiento del revestimiento metálico lo convierten en una solución ideal para edificios públicos como escuelas, hospitales y estaciones.

Zonas especiales

Especialmente en zonas como las costeras, con elevada humedad y niebla salina, los revestimientos metálicos funcionan muy bien y pueden proteger a largo plazo las paredes exteriores de los edificios.

Tecnología de producción y procesamiento de la máquina de revestimiento metálico

La máquina de revestimiento de metal adopta la tecnología de formación de doblado en frío, y los pasos específicos incluyen:

Alimentación de materias primas

Seleccione la bobina metálica de especificaciones adecuadas y entréguela en la formadora a través del sistema de alimentación.

Proceso de formación

Utilice moldes de alta precisión para procesar la bobina metálica en el diseño de ángulo de 90 grados requerido u otras estructuras específicas.

Cortar y recortar

Corte la longitud de la chapa según los requisitos del cliente y realice el tratamiento de los bordes para garantizar la seguridad y el aspecto.

Tratamiento de superficies

Según los requisitos del escenario de aplicación, se lleva a cabo un tratamiento de pulverización, revestimiento o chapado para mejorar la durabilidad y el efecto decorativo.