Cambios tecnológicos y sistemas industriales, nos dedicamos a

Proporciona a Seds las mejores y más económicas soluciones a sus valiosos clientes.

El papel del borde de goteo y del borde del tejado en los sistemas de cubiertas: Una guía completa

diferentes tipos de maquinas perfiladoras en frio. Somos una fábrica con una larga historia, dedicada al diseño y fabricación de maquinas perfiladoras desde 2006. Las máquinas que podemos producir incluyen: máquina formadora de tejas, máquina formadora de correas cz, máquina formadora de quillas de acero ligero, máquina de estampado de metal, máquina formadora de sistemas de puertas, máquina formadora de sistemas de techos, máquina de soldadura de tuberías de alta frecuencia, línea de corte longitudinal, línea de corte a la medida, máquina formadora de sistemas de estantes, máquina formadora de cubiertas de piso, línea de producción de tejas de piedra de color, máquina laminadora en caliente, etc.

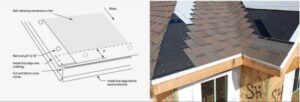

El borde de goteo y el borde del tejado son dos componentes esenciales de los sistemas de tejado que desempeñan un papel crucial en la protección de los edificios contra los daños causados por el agua. Estos componentes suelen fabricarse con máquinas perfiladoras, que son herramientas versátiles y eficientes utilizadas en la industria manufacturera.

El borde de goteo es una tira metálica que se instala a lo largo del borde del tejado para dirigir el agua lejos de la imposta y el sofito, evitando daños por agua y protegiendo la estructura del edificio. Suele fabricarse con perfiladoras, que doblan y moldean las chapas para darles la forma deseada. La perfiladora utiliza una serie de rodillos para moldear gradualmente el metal hasta darle la forma deseada, lo que garantiza la consistencia y precisión del producto final. El borde de goteo es especialmente útil en zonas de alta pluviosidad, ya que ayuda a canalizar el agua lejos del edificio y evita su acumulación.

El borde de tejado, por su parte, es un embellecedor metálico que se instala a lo largo del perímetro del tejado para proporcionar un aspecto pulcro y acabado. También se fabrica con perfiladoras, que pueden crear formas y diseños complejos. La perfiladora puede doblar y dar forma al metal en patrones intrincados, lo que permite un aspecto personalizado que complementa la arquitectura del edificio. El borde del tejado puede fabricarse con diversos materiales, como aluminio, acero y cobre, y a menudo se recubre para resistir la corrosión y la intemperie.

Las perfiladoras se utilizan para fabricar tanto bordes de goteo como bordes de tejado. Estas máquinas están diseñadas para procesar chapas metálicas y transformarlas en la forma deseada. Constan de una serie de rodillos que doblan gradualmente el metal hasta darle la forma deseada. El proceso es automatizado y eficaz, lo que lo convierte en una opción popular para la producción en masa. La perfiladora puede programarse para crear diferentes formas y tamaños, en función de los requisitos específicos del proyecto.

Para utilizar una perfiladora, primero se carga la chapa metálica en el sistema de alimentación de la máquina. A continuación, la máquina guía la chapa a través de los rodillos, dándole gradualmente la forma deseada. El operario puede ajustar la velocidad y la presión de los rodillos para garantizar un resultado uniforme y preciso. La máquina también puede incorporar funciones adicionales, como corte y punzonado, para crear productos personalizados.

Cuando se utiliza una perfiladora para fabricar bordes de goteo o bordes de tejado, es esencial seguir las directrices y procedimientos de seguridad. Los operarios deben llevar equipo de protección y asegurarse de que la máquina recibe el mantenimiento adecuado. También deben recibir formación sobre el uso correcto de la máquina y ser conscientes de cualquier peligro potencial.

En conclusión, el borde de goteo y el borde de cubierta son componentes cruciales en los sistemas de cubierta que proporcionan protección y valor estético. Se fabrican con perfiladoras, que son herramientas eficaces y versátiles utilizadas en la industria manufacturera. Con un uso y mantenimiento adecuados, las perfiladoras pueden fabricar productos de alta calidad que satisfagan las necesidades específicas del proyecto. Al comprender la importancia de estos componentes y el proceso de su producción, los propietarios de edificios y los contratistas pueden garantizar la longevidad y durabilidad de sus sistemas de cubiertas.

Manejo de una perfiladora: Guía del usuario

Las perfiladoras son potentes herramientas utilizadas en la industria manufacturera para fabricar una gran variedad de productos metálicos, incluidos los bordes de goteo y los bordes de tejado. Para garantizar un funcionamiento seguro y eficiente, es esencial seguir los pasos que se indican a continuación:

Preparación: Antes de poner en marcha la máquina, asegúrese de que la chapa está correctamente alineada y cargada en el sistema de alimentación. Compruebe la configuración de la máquina y realice los ajustes necesarios para asegurarse de que está lista para su uso. Esto incluye comprobar los rodillos, las herramientas de corte y cualquier característica adicional.

Seguridad: Lleve equipo de protección, como guantes y gafas de seguridad, para protegerse de posibles peligros. Asegúrese de que la máquina está correctamente mantenida y de que dispone de todos los dispositivos de seguridad.

Puesta en marcha de la máquina: Encienda la máquina y deje que se caliente. Ajuste la velocidad y la presión deseadas para los rodillos, en función del grosor y el material de la chapa.

Alimentación de la chapa: Guíe la chapa a través de los rodillos, asegurándose de que está correctamente alineada y de que los rodillos están enganchados. Aumente gradualmente la velocidad a medida que la chapa pasa por la máquina.

Supervisión: Vigile de cerca el funcionamiento de la máquina y realice los ajustes necesarios en los rodillos o la configuración. Asegúrese de que la chapa adquiere la forma deseada y de que no hay defectos ni problemas.

Corte y acabado: Una vez conformada la chapa, utilice la herramienta de corte para recortarla a la longitud deseada. Aplique al producto los revestimientos o acabados necesarios para protegerlo de la corrosión y la intemperie.

Mantenimiento: Limpie y mantenga regularmente la máquina para garantizar su longevidad y fiabilidad. Esto incluye la comprobación del desgaste de los rodillos y otros componentes.

Siguiendo estos pasos, los usuarios pueden fabricar productos de borde de goteo y borde de tejado de alta calidad que satisfagan las necesidades específicas de sus proyectos. Es importante seguir las directrices y procedimientos de seguridad y recibir formación sobre el uso adecuado de la máquina para evitar accidentes o lesiones. Con un uso y mantenimiento adecuados, las perfiladoras pueden proporcionar una solución fiable y eficaz para la fabricación de productos metálicos.

En resumen, el manejo de una perfiladora requiere prestar atención a los detalles y respetar las directrices de seguridad. Siguiendo estos pasos y manteniendo la máquina, los usuarios pueden fabricar productos de alta calidad que satisfagan las necesidades de sus proyectos. Tanto si está produciendo bordes de goteo como bordes de tejado, una perfiladora es una herramienta valiosa que puede agilizar el proceso de fabricación y garantizar una producción uniforme y precisa.

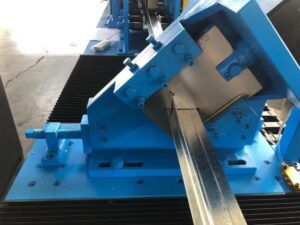

El bastidor de la máquina adopta una estructura de soldadura de chapa de acero de 20 mm de espesor. Garantiza que la máquina pueda soportar rodillos y bastidores de rodillos de mayor peso.

El material del rodillo es GCr12 MOV

Diámetro del rodillo: 60 mm

El material del rodillo es 40Cr

El bastidor del eje del rodillo es: bastidor del molde

Velocidad de funcionamiento de la máquina: 45 m por minuto

Material de la cuchilla de corte: GCr12

Método de corte: servo tracking cutting

Potencia del servomotor: 2,3 kW

Potencia del motor de accionamiento: 7,5+7,5 kW

Potencia de corte: 5,5 kW

¿Por qué elegirnos?

Servicio integral OEM/ODM y personalización

Servicio posventa completo

Proporcionar OEM、ODM

2.Diseño técnico:realizar perfiles de dibujo y dibujo de máquinas en 3D

3.determinar la configuración y la producción

4.pruebas antes de la entrega

6.Orientaciones técnicas

7.Servicio posventa:Servicios de instalación de máquinas complejas y visitas periódicas al cliente

Con la confianza de más de 95800 empresas

empresas de alta calidad. A través de la cooperación con nosotros, han recibido

fuerte apoyo y logrado avances y desarrollo empresariales.