Technologische Veränderungen & Industrielle Systeme, wir widmen uns

Bietet Seds die besten und wirtschaftlichsten Lösungen für geschätzte Kunden.

Kabelleiterrahmen Z-Profil Walzprofiliermaschine

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc. Cable ladder frame Z profile rolling forming machine is designed to make the ladder frame in batch fully automatically.

Kabelleiterrahmen Z-Profil Walzprofiliermaschine

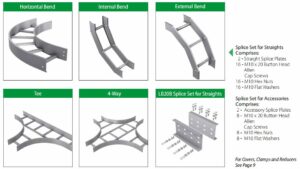

Cable ladder frame Z profile rolling forming machine is designed to make the ladder frame in batch fully automatically. This cable ladder range is a complete cable support system that is easily assembled on site and it is is specifically designed to carry electrical cables in horizontally mounted, heavy duty industrial and mining applications. Here are some usage cases for your reference:

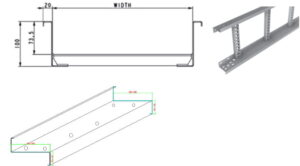

This type ladder is composed by two parts, the Z frame part and the C connection beam with punching. Here is the drawing profiles for your reference. By this type, the ladder could be any width. And for the Z frame, you can choose to do the punching online or offline.

Cable ladder frame Z profile rolling forming machine:

Z frame roll forming parameters for your reference:

Main motor power: 18.5kw

Drive: Chain

Main shaft dia: ¢85mm, material: 45﹟refined forge steel

Roller material: GCr15 bearing steel, quenching HRC58-62,surface coated chrome with thickness 0.05mm

Roll station: 16stations with 7 leveling rollers

Raw material: Black steel or galvanized steel

Thickness of raw material: 2-3mm

Working speed: about 7-15m/min(include cutting time)

Coder: OMROM

PLC: YASKAWA , made in Japan. 380V 50HZ(Depend on customer)

Computer operating panel: touching screen

And for the shearing system:

Hydraulic cutting

Four sets of the cutting mould to replace for different size

Hydraulic power: 5.5KW

Hydraulic pressure: 20Mpa

Blade material: Cr12mov, quenched 58°-62°

This machine we design is slow speed and more economic. If you want to make more sizes and like more high speed machine, we could make also. There are other types same working principle, we could also make.

For this type machine, if you want to know more information, please contact us at any time.

Warum sollten Sie uns wählen?

OEM/ODM und kundenspezifische Anpassung aus einer Hand

Umfassende Unterstützung durch den Kundendienst

Bereitstellung von OEM、ODM

2.Technischer Entwurf: Anfertigung von Profilzeichnungen und 3D-Maschinenzeichnungen

3.die Konfiguration und die Produktion zu bestimmen

4.Prüfung vor der Auslieferung

6.Technische Anleitung

7.Kundendienst: Installationsdienste für komplexe Maschinen und regelmäßige Kundenbesuche

95800+ Unternehmen vertrauen auf uns

hochwertige Unternehmen. Durch die Zusammenarbeit mit uns haben sie Folgendes erhalten

starke Unterstützung und erzielte geschäftliche Durchbrüche und Entwicklungen.