Technologische Veränderungen & Industrielle Systeme, wir widmen uns

Bietet Seds die besten und wirtschaftlichsten Lösungen für geschätzte Kunden.

Automatic hydraulic decoiler for metal roofing sheet rolling forming machine

verschiedene Arten von Kaltwalzmaschinen. Wir sind eine Fabrik mit einer langen Geschichte, die sich seit 2006 mit der Entwicklung und Herstellung von Walzprofiliermaschinen beschäftigt. Die Maschinen, die wir produzieren können, umfassen: Dachziegel machen Maschine, cz Pfette machen Maschine, leichte Stahl Kiel machen Maschine, Metallprägung Maschine, Tür System bilden Maschine, Decke System bilden Maschine, Hochfrequenz-Rohr-Schweißmaschine, Schlitz Linie, auf Länge geschnitten Linie, Regal System bilden Maschine, Bodenbelag bilden Maschine, Farbe Stein Fliese Produktionslinie, heiße Laminierung gefilmt Maschine, etc.

Automatic hydraulic decoiler for metal roofing sheet rolling forming machine

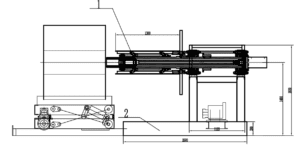

Automatic hydraulic decoiler for metal roofing sheet rolling forming machine is designed for supporting metal rolling machine work. A hydraulic uncoiler, which supports the rolling plate and provides tension to the steel strip, is composed of a frame, a main shaft, an expansion and contraction drum, and a braking device.

- a) Main frame: Made of forged and welded bearing seats made of section steel, A3 steel plate, and # 45 steel, and subjected to annealing and qualitative treatment without deformation; Two bearing seats are bored at once to ensure the concentricity of the spindle installation and prevent radial runout.

- b) Spindle: Made of a 40Gr round steel drill with a diameter of 85mm through hole, quenched and tempered, and then finely turned. The working face has a diameter of 190mm and a load-bearing capacity of 15 tons.

- c)Expansion and contraction shaft: adopt slider type push pull expansion drum form; Four curved plates and a pair of linear cutting sliders, with a diameter increase or decrease Ф 460~ Ф 520; The effective working length is 1300mm, and the overall mandrel ensures the concentricity of the drum during expansion and contraction. The surface of the drum is electroplated with hard chromium.

- d) Brake device: adopts pneumatic disc brake components, with adjustable braking force. When parking, the brake is tightened, and when driving, the brake is pulled to ensure that it will not loosen during standby and startup states, to avoid scratching the board surface during loosening.

- e) Hydraulic power:push pull expansion and contraction mandrel: hydraulic cylinder model and specification: FA- Ф one hundred and twenty-five × 130mm, using rotary joint oil supply method; Pressure lifting hydraulic cylinder FA- Ф sixty-three × 600 mm.

Automatic hydraulic decoiler for metal rolling forming machine types:

The hydraulic automatic decoiler has the following types:

- The decoiler with short shaft for purline rolling forming machine.

- Long shaft for wide coil roofing sheet machine

- Hydraulic decoiler for slitting or cut to length machine.

- Automatic decoiler for roofing sheet machine.

By the different functions and then the hydraulic decoiler we can design them like:

- Fixed type decoiler

- Movable hydraulic decoiler for many machines.

- The loading car is fixed type

- Or X table loading car

- The decoiler withe pressing arm.

- The decoiler with the supporting table.

- The decoiler with the brake.

Advantages of Zhongtuo hydraulic decoiler:

- Electrical parts: Equipped with world famous brand “Schneider”electrical parts, more safety and reliable.The operation of the equipment is more safe, reliable and stable.

- Pneumatic braking system: Can stop the rotate of coil immediately when required, avoid unnecessary coil output.

Fast braking, more safer. The matching high-speed forming machine needs faster uncoiling speed, and the pneumatic brake can provide greater braking force. Customers need to be equipped with their own compressed air source.

- Expanding device:Four arms expanding device with sliding block can provide more powerful force to fixing the coil, The synchronous action can avoid the deformation of the coil. The block installed on the the arms can suit the coils with bigger inner diameter.

- Limit Switch Arm. And rollers on frame. It can automatically start and stop the rotate of coil according to the rate of progress of forming machine.It can also be installed the other side of the machine for opposite feeding direction. we have reserved the installation bracket. The rollers on the both sides of frame can avoid scratch of coil when it run out.

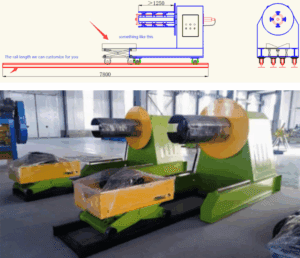

- X table hydraulic decoiler.

- The decoiler movable type with rail

The rail length we can design according to your requirement like 6 meter 8 meters or others. By the movable type,it could be used together with many rolling forming machines. And then you can save lots of cost and space.

For the hydraulic decoiler we can make it to 5 ton, 7 ton 7 ton , 10 ton 15 ton 20 Ton and more, fully design according to your requirements. For more information, please contact us at any time.

Warum sollten Sie uns wählen?

OEM/ODM und kundenspezifische Anpassung aus einer Hand

Umfassende Unterstützung durch den Kundendienst

Bereitstellung von OEM、ODM

2.Technischer Entwurf: Anfertigung von Profilzeichnungen und 3D-Maschinenzeichnungen

3.die Konfiguration und die Produktion zu bestimmen

4.Prüfung vor der Auslieferung

6.Technische Anleitung

7.Kundendienst: Installationsdienste für komplexe Maschinen und regelmäßige Kundenbesuche

95800+ Unternehmen vertrauen auf uns

hochwertige Unternehmen. Durch die Zusammenarbeit mit uns haben sie Folgendes erhalten

starke Unterstützung und erzielte geschäftliche Durchbrüche und Entwicklungen.