في بيرو، يتم تصنيع ألواح الأسقف عادةً باستخدام ماكينات تشكيل الصفائح المعدنية. تقوم هذه الماكينات بتحويل لفائف الصلب المجلفن أو المطلي مسبقًا أو غيرها من المواد إلى مقاطع محددة تستخدم في الأسقف وكسوة الجدران.

أنواع ماكينات التشكيل بالدلفنة المتوفرة في بيرو:

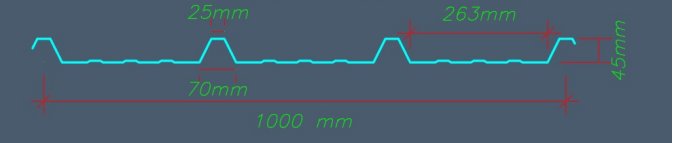

ماكينات تشكيل الصفائح شبه المنحرفة (TR4، TR5): مصممة لإنتاج المقاطع الجانبية شبه المنحرفة الشائعة في السوق البيروفية، مثل TR4 و TR5. يمكن أن تكون هذه الماكينات أحادية الطبقة أو مزدوجة الطبقة، مما يسمح بإنتاج نوعين من التشكيلات الجانبية على ماكينة واحدة.

ماكينات تشكيل الصفائح المموجة: تستخدم لتصنيع الصفائح المموجة، التي تستخدم عادةً في الأسقف والجدران نظراً لقوتها وجمالياتها.

ماكينات تشكيل البلاط المعدني: تُستخدم لإنتاج صفائح تحاكي مظهر البلاط التقليدي، مما يوفر بديلاً متيناً وقليل الصيانة.

اعتبارات عند اختيار ماكينة التشكيل بالدلفنة:

المواصفات الفنية: عرض التغذية، وسُمك المادة، وسرعة الإنتاج، ونوع القطع (هيدروليكي أو ميكانيكي).

المرونة: القدرة على التكيف مع المواد والملامح المختلفة وفقًا لاحتياجات السوق.

دعم وخدمة ما بعد البيع: توافر قطع الغيار والصيانة والمساعدة الفنية المحلية.

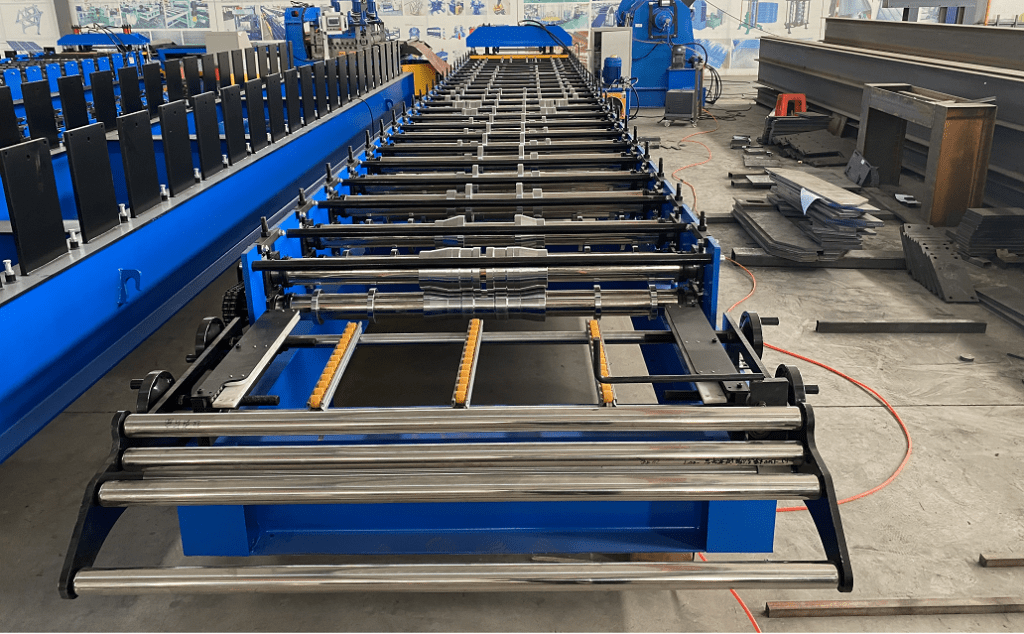

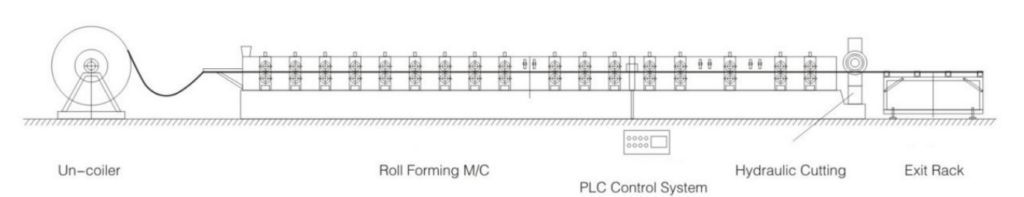

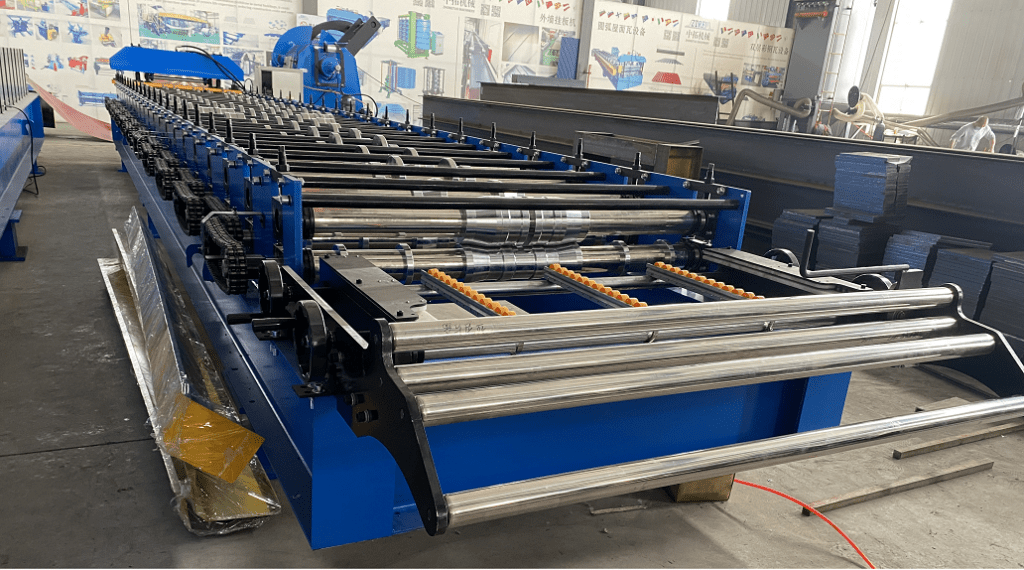

تدفق عمل ماكينة تشكيل ألواح السقف الدوارة Tr4:

فك اللف - اللفة الرئيسية السابقة - القطع الهيدروليكي - طاولة تجميع المنتجات

طلب تقديم العروض

كيف يتم تثبيت الجهاز؟

سنقدم لك دليل الماكينة ومخطط الأسلاك للمساعدة في تركيب الماكينة.

العملية سهلة للغاية، وتحتاج فقط إلى ساعتين حتى لو لم تكن لديك أي خبرة في مجال الماكينات.

ماذا عن إنتاجية عمل الماكينة؟

سرعة الماكينة 15 م/دقيقة، إذا كان ذلك وفقًا لـ 8 ساعات عمل يوميًا، كل لوح سقف بطول 3 م,

يوم واحد يمكن أن ينتج 240 قطعة من صفائح السقف.

ماذا عن عمر خدمة الماكينة؟

إذا تم استخدامها وصيانتها كالمعتاد، ستعمل الآلة لأكثر من 15 عامًا دون أي مشكلة.