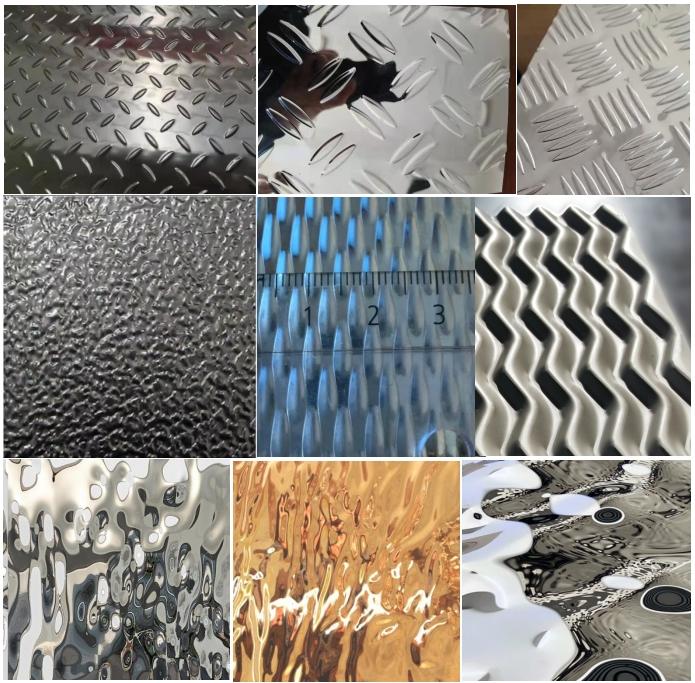

تبرز ماكينة النقش على المعادن ZTRFM، والمعروفة أيضًا باسم ماكينة النقش على المعادن الجصية أو ماكينة صنع الألواح ذات المربعات كخيار أول لمحترفي تشغيل المعادن الذين يبحثون عن الدقة والتنوع والكفاءة في عمليات معالجة الأسطح. وتمثل هذه الماكينة المبتكرة أحدث ما توصلت إليه التكنولوجيا في صناعة معالجة المعادن، حيث توفر قدرات لا مثيل لها لصياغة الأنماط والزخارف المعقدة على أسطح الصفائح المعدنية.

يكمن في قلب ماكينة ZTRFM مبدأ عملها المتطور المتجذر في علم التشوه الفيزيائي. من خلال تطبيق القوة الميكانيكية بدقة على المادة المعدنية، فإنها تُحدِث تشوهًا بلاستيكيًا على السطح، مما يحول الصفائح العادية إلى أعمال فنية مزينة بأنماط أو زخارف مصممة مسبقًا. ويضمن هذا التحكم الدقيق في الضغط وحركة القالب أن تكون كل التفاصيل المنقوشة واضحة ونقية وتدوم طويلاً، وذلك بفضل استخدام قوالب عالية الجودة مصنوعة من الكربيد الأسمنتي أو مواد متينة مماثلة.

إن تعدد استخدامات ماكينة نقش المعادن ZTRFM لا مثيل له. فهي تتجاوز التطبيقات التقليدية، فهي لا تعمل فقط كأداة إبداعية للمنتجات المعدنية المزخرفة في قطاعات مثل التصميم المعماري وأجهزة الأثاث والديكور الداخلي ولكن أيضًا كعنصر حيوي في التصنيع عالي التقنية. في صناعة السيارات، على سبيل المثال، لا غنى عن هذه الآلات في صناعة المكونات الداخلية ذات القوام الفريد الذي يرفع من المظهر الجمالي والتجربة الملموسة للمركبات. وبالمثل، في مجال هندسة الطيران، حيث الدقة والمتانة أمران أساسيان، تتيح ماكينات ZTRFM إنتاج أجزاء معدنية وظيفية ذات ميزات سطحية معقدة.

وعلاوة على ذلك، تجسد ماكينة النقش على المعادن ZTRFM روح التحسين المستمر والابتكار. فمع تقدم التكنولوجيا وتطور متطلبات السوق، يتم تحسين وظائف الماكينة وأدائها باستمرار لتلبية مجموعة واسعة من احتياجات الإنتاج. سواء كان الأمر يتعلق بتحقيق تفاصيل أدق أو سرعات معالجة أسرع أو توافق أوسع للمواد، تظل ZTRFM في طليعة الابتكار، مما يضمن للمستخدمين الاستفادة من الإمكانات الكاملة لمعالجة أسطح المعادن.

وعلاوة على ذلك، فإن سهولة التشغيل والصيانة التي توفرها ماكينة النقش المعدني ZTRFM تميزها عن غيرها. إن عناصر التحكم البديهية والواجهات سهلة الاستخدام تجعلها في متناول المشغلين من مختلف مستويات المهارة، في حين أن البنية القوية والمكونات عالية الجودة تقلل من وقت التوقف عن العمل ومتطلبات الصيانة. وهذا يضمن أقصى إنتاجية وفعالية من حيث التكلفة للشركات من جميع الأحجام.

في الختام، يُعد اختيار ماكينة النقش على المعادن ZTRFM قرارًا استراتيجيًا يفتح عالمًا من الإمكانيات لمحترفي تشغيل المعادن. فهي تجمع بين الدقة وتعدد الاستخدامات والكفاءة في حزمة واحدة متطورة، مما يمكّن المستخدمين من إنشاء منتجات معدنية مذهلة تلبي أعلى معايير التصميم والوظائف. ومع تطور الصناعة، تظل ZTRFM ملتزمة بالبقاء في الطليعة، مما يضمن استمرار ماكيناتها في تقديم أداء وقيمة لا مثيل لها.

ميزتنا:

1- بكرات النقش مصنوعة من سبائك الفولاذ المطروق من خلال سبائك الفولاذ المطروق بالتردد المتوسط، HRC 55-58.

2- وضع القيادة: تنظيم السرعة عن طريق تحويل التردد

3-إطار الماكينة: إطار القوس الذي نستخدمه من الفولاذ الصلب، وليس الأنبوب المربع الملحوم. إطار الماكينة لدينا أكثر قوة

4-بكرات النقش قابلة للتغيير، إذا كنت بحاجة إلى أنماط أخرى في المستقبل، يمكننا تصميم وصنع بكرات جديدة، أو نقدم لك رسم تصميم، يمكنك معالجتها في المصنع المحلي

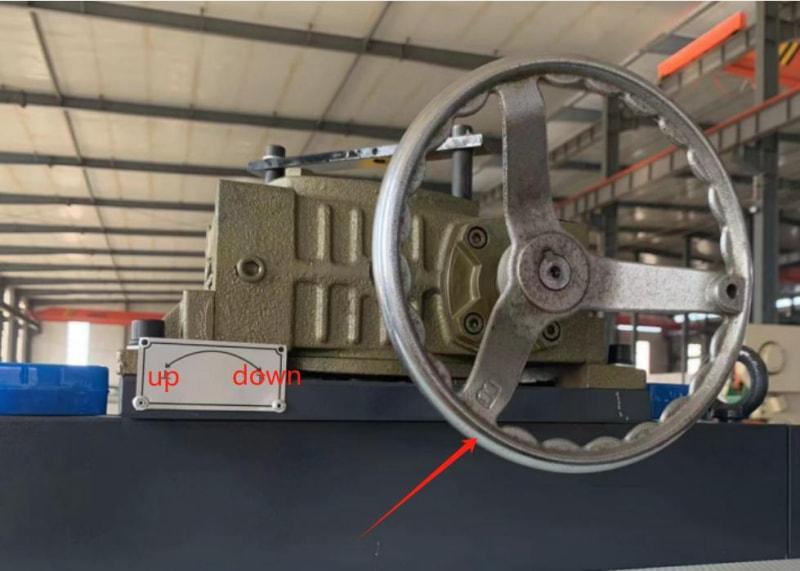

كيفية ضبط الفجوة بين بكرتين هي أكثر الأسئلة التي يطرحها العملاء. إنه سهل التشغيل، يتم ضبطه من خلال العجلة اليدوية كما في الصورة أدناه.