Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

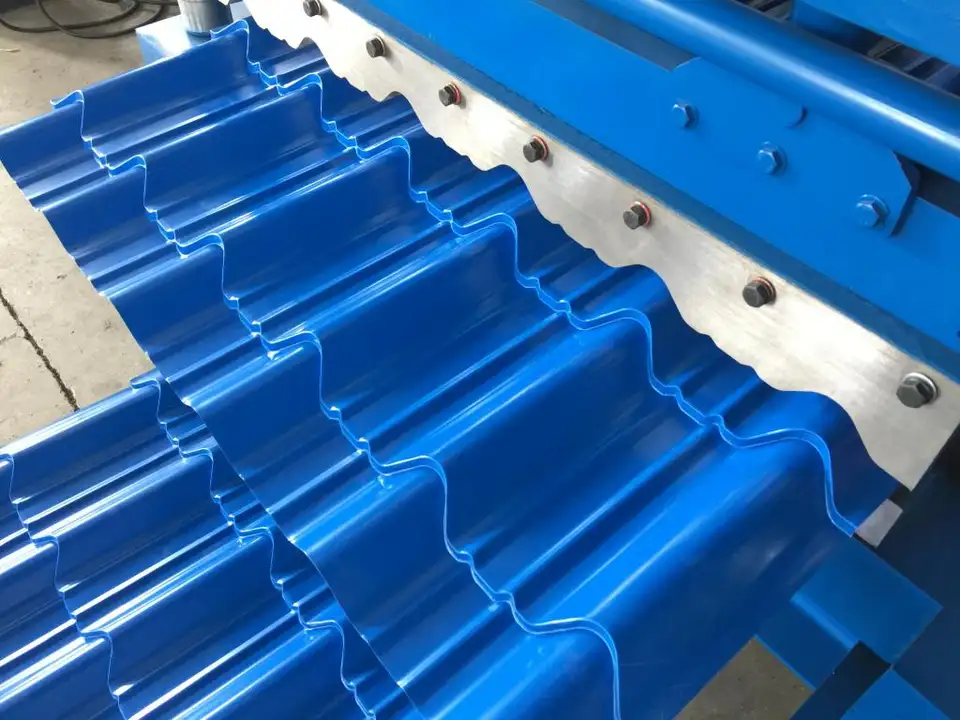

Step tile profile rolling forming machine

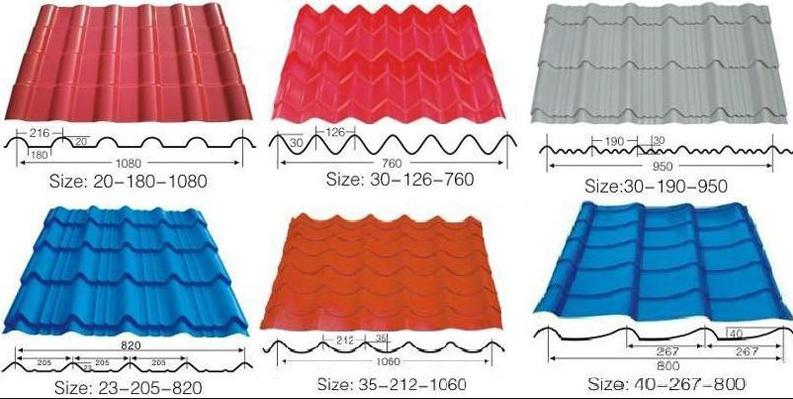

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

In the world of modern construction and metal processing, efficiency and precision are the keys to success. Our Step Tile Profile Rolling Forming Machine is here to revolutionize your production process. This state – of – the – art machine is designed to transform flat metal sheets into high – quality step tiles with remarkable speed and accuracy. Whether you are in the roofing industry, building large – scale industrial structures, or involved in custom metalwork projects, our step tile profile rolling forming machine is the perfect solution for you.

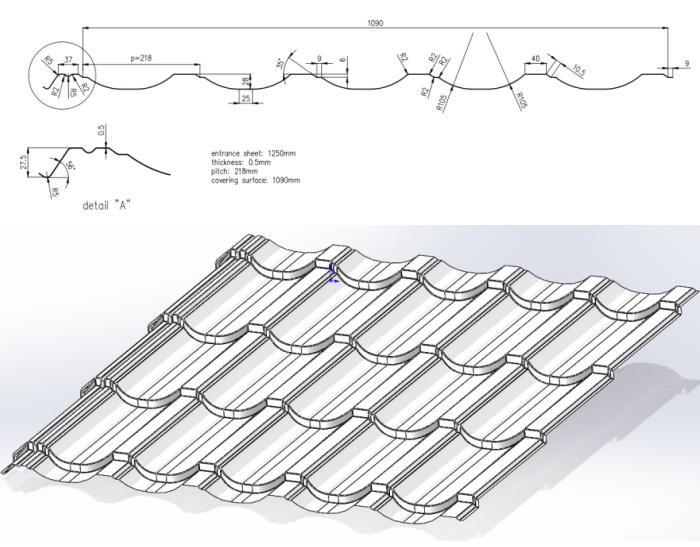

Customer drawing profile:

Material thickness: 0.4mm 0.5mm

Step height: 20

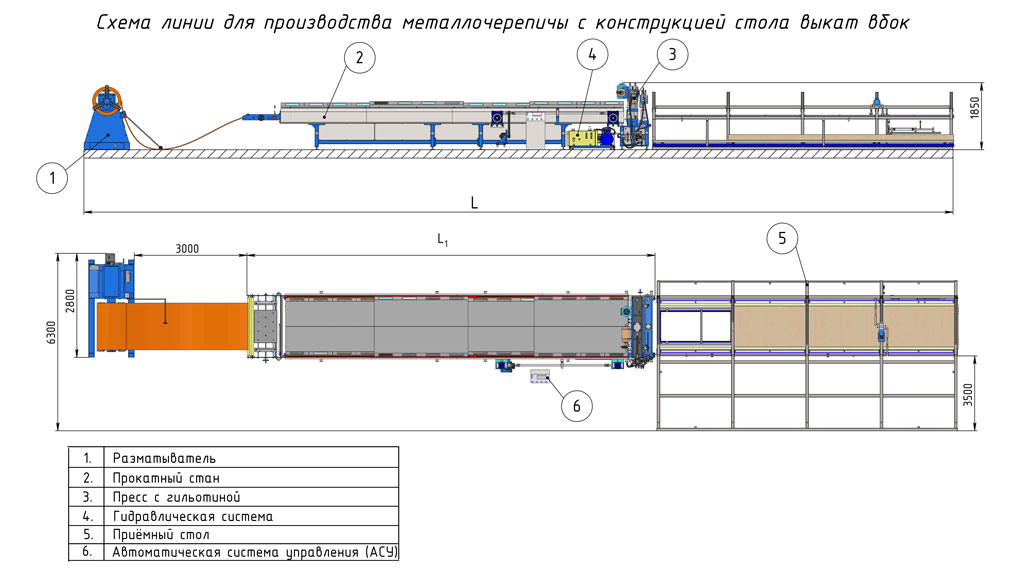

Working flow:

Equipment Configuration

Rolling Mill;

Press with Guillotine;

Hydraulic System;

Automatic Control System

Requirements for the finished products:

– Maximum deviations of profile dimensions are indicated in the drawing.

– waviness of the edge shelves – no more than 1 mm

– camber – no more than 1 mm/m

– screw-shape – no more than 1°

– maximum deviation along the length: + 1 mm for a length up to 2,0 m; + 0,5 mm/m for a length more than 2.0 m.

– When carrying out fit-up assembly test of the products on a flat surface, the maximum gap between the covering and covered parts of the product along the entire length of the product should not exceed 1,0 mm

– The difference in panels diagonals should not exceed 2 mm at 1 m of product length and no more than 4 mm at any length.

– The length spread of the transverse wave step should not exceed + 0,5 mm for panels from one order.

Appearance requirements of finished products

-Scratches, abrasions, cracking and other damage of the protective and decorative polymer coating of the front and back sides are not allowed

-Visible creases on the surface of products are not allowed.

-Deformation of the edge after cutting (burrs, nicks are allowed) – no more than 10% of the metal thickness.

1.Parameters of the sheet blank form:

- thickness – 0.35 mm…0.5 mm;

- width – 1250 mm.

2.Standardized mechanical properties of the blank material:

- yield strength of the steel base – 280…320 N/mm²;

- tensile strength of the steel base – not more than 450 N/mm².

3.Technical conditions for the supply of blank material: with protective-decorative paint and varnish coating – thin-sheet roll.

Machine Technical Specifications

| Item | Conditions and Operating Parameters of Machine | Value |

| 1 | Operating mode of the line | setup / automatic |

| 2 | Productivity taking into account rolling and stamping, but without considering the cutting of the profile to a size | of 8-10 meters per minute |

| 3 | Voltage of the power supply network at a frequency of 50 Hz ± 0.4 Hz | 3 phases, 380 V |

Technical Description of Completeness:

| Rolling mill | ||

| 2.1 | Device for threading and guiding the strip

Execution example see Fig. 4. |

With a roller knife, mechanical. |

| 2.2 | Profiling method

Execution example see. |

“Sequential profiling method,” starting with the central corrugation, then two adjacent ones, then another two adjacent ones, and so on to the end. |

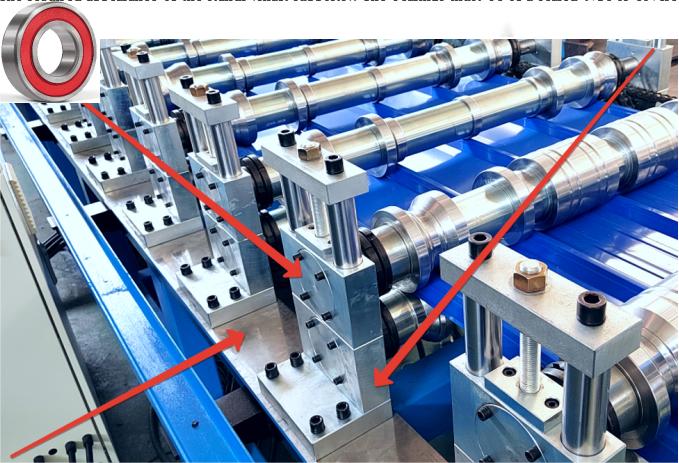

| 2.3 | Number of stands

Shaft diameter: 80mm |

16 roller station separated molding rolling forming |

| 2.4 | Frame

Execution example see |

The surface of the frame must be milled and drilled with holes for mounting the stations. Milling and drilling must be performed on a milling center. |

| 2.5 | Stations (shaft supports)

Execution example see |

Must be made of steel, with high precision and ensure assembly and installation on the frame, without welding. Must have anti-corrosion coating. |

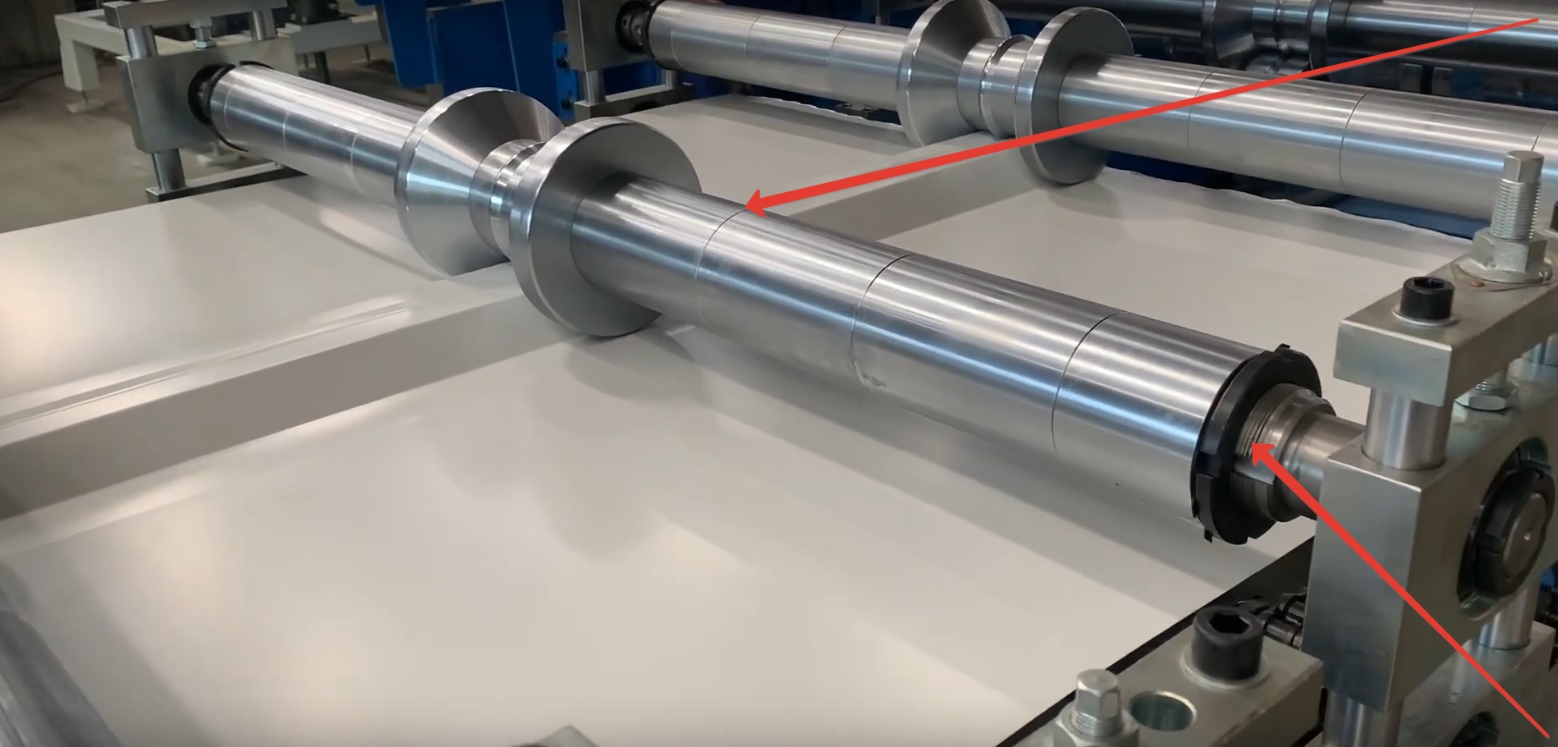

| 2.6 | Type of roller mounting

Execution example see |

On a key, through spacers. |

| 2.7 | Installed power | Two servo motors, 5.5 + 5.5 kW. |

| 2.8 | Material of rollers steel | 40Х or #45, surface hard chroming |

| 2.9 | Roller knife at the beginning of the rolling mill | Mechanical (knife movement by hand) |

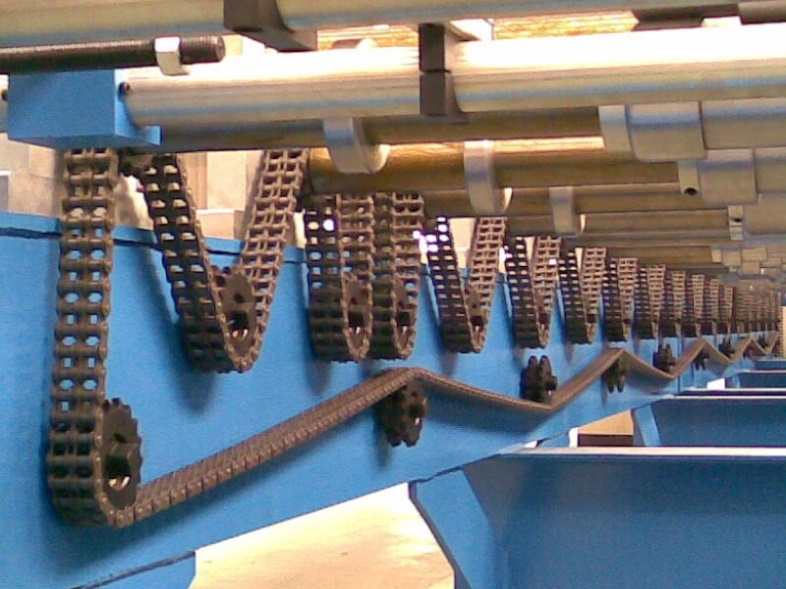

| 2.9 | Torque transmission Implementation example | Two loops of chain, with tensioners. |

| 2.10 | Emergency Stop Cable | around the perimeter of the rolling mill |

Motor shearing or manual cutter

Servo motor

| Press and guillotine | ||

| 3.1 | Drive type | Hydraulic |

| 3.2 | Automatic emulsion injection system | Nozzles, drive power 1 kW. |

| The metal tile profile production technology includes the mandatory injection of emulsion, which allows for stable quality and increases the service life of the tool. | ||

| 3.3 | Guillotine | Direct cut |

| 3.4 | Active type guillotine | yes, Implementation example Fig. |

| The active type guillotine provides two positions for the lower blade: working and initial. In the working position, the lower

blade of the guillotine is raised before cutting the final profile and returns to the initial position during the operation of the rolling mill. This eliminates prohibited lengths of the finished profile and allows for the production of metal tiles with a wave length of 350 and 400 mm. |

||

With the oiling spraying and it also can reduce the damage of the surface of the coil.

| Hydraulic System | ||

| 4.1 | Power of the main drive | 11 kW |

| 4.2 | Power of the cooling system | 1.5 kW, cooling circuit with radiator and fan |

| 4.3 | Tank volume | 300 liters |

| 4.4 | Working pressure in the system | 12 MPa |

| 4.5 | Hydraulic accumulator | Yes |

| Receiving table. Implementation example | ||

| 5.1 | Type | stacker |

| 5.2 | Length of the finished product | 1 – 6 m |

| 5.3 | Installed power | 1.1 kW |

| 5.4 | Platform load, no more than | 500 kg one meter |

| 5.5 | Stack height | no more than 350 mm, including the height of the pallet. |

| 5.6 | Direction of the platform rollout | forward |

| Automatic Control System | ||

| 6.1 | Controlled parameters: | – rolling speed;

– count-length of products; – adjustment of pauses in the technological cycle; – production task; – program for choosing the length of the “steps”. |

| 6.2 | Interface | Russian / English |

| 6.3 | Indicators: | main technological parameters, notification of emergencies and errors |

The required appearance of the stands (shaft supports). The bearings must be of a sealed type or covered

The required design of the frame with a milled surface.

The required design of the frame and stands.

The roller mounting on a key, through spacer rings.

The entire set of tools on the shaft is tightened at the edges with nuts.

The required design of the torque transmission.

A three-row chain with tensioners shall be used:

The design of the “Sequential method of profiling.

Type of tensioners.

Active type of stamp. The lower part of the stamp is at the starting level of stamping. Two hydraulic cylinders press from the bottom with a force of approximately 20 bar. When the upper part of the stamp descends, it does so using hydraulic plungers, which press with a force of approximately 100 bar. The upper part of the stamp presses the metal against the lower part and, overcoming its resistance, presses the metal and the lower part of the stamp to the required depth. After that, the upper part of the stamp rises, the movement of the metal begins, and at this moment, the lower part of the stamp is lifted using hydraulic cylinders. Then the cycle repeats.

View of the active die at work, in raised and lowered position.

Adjustment of stamping depth. The depth is adjusted with the help of a 6 mm thick metal plate, which is slid under or out from the lower part of the stamp. The operation is done manually, by turning the handwheel.

View of the mechanism for adjusting stamping depth.

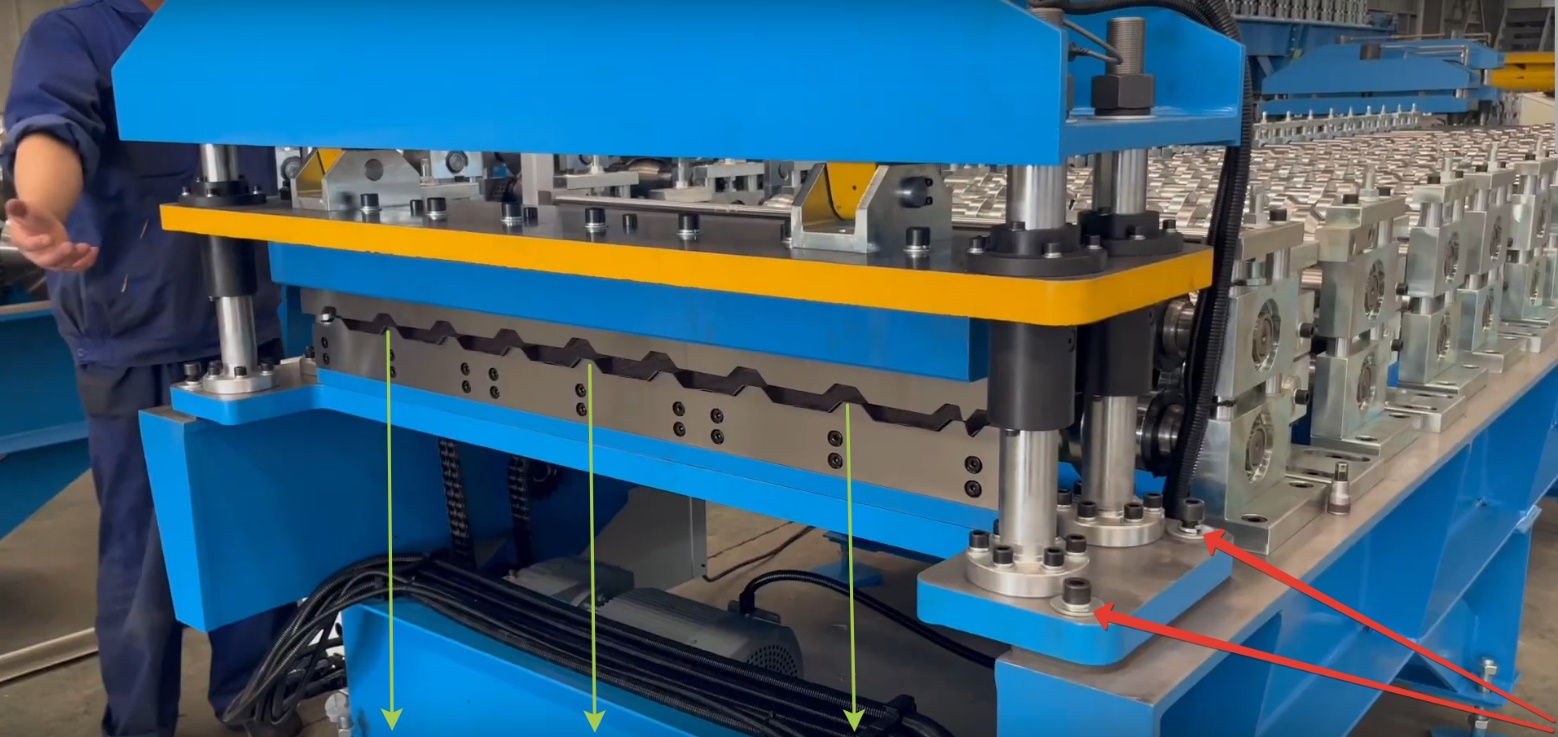

Green arrows indicate how the metal sheet should fall. This means that after the cut, nothing should prevent the sheet from falling down onto the pallet.

The design of the shears should not hinder the finished sheet from falling down. This will allow the client to use a simple receiving table without a conveyor belt.

Active type cross-cutting shears. During stamp operation, the lower blade is in the down position and removed from the cutting area to prevent deformation of the metal around the blade during stamping. When it is necessary to make a cut, the lower blade is raised and fixed at the required level. The upper blade then makes the cut, after which the lower blade is lowered again. The cycle then repeats.

The location of the mold stamping mechanism and the metal cutting shears should be separate, but should be located as close to each other as possible.

View of the Press and Guillotine arrangement.

View of the hydraulic station with cooling system and hydraulic accumulator.

The hydraulic station should have a capacity of 300 liters, power of 11 kW. It should have an active cooling circuit with a radiator and fan, power 1.1 kW.

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.