In the current stage of rapid technological development, the manufacturing industry continues to make strides towards automation and intelligence. The newly developed fully automatic CZ profile steel integrated machine is like a shining pearl in the industry, injecting new vitality into the field of profile steel production and bringing about many significant changes.

1). Outstanding fully automatic function performance

The fully automatic features of this all-in-one machine are impressive. It smoothly realizes the conversion from C-type to Z-type, and is easy to operate without complicated manual intervention. It can be easily switched with only simple operations. At the same time, it also shows extraordinary automation skills in adjusting the thickness gap of equipment raw materials. Whether it is dealing with a variety of production orders or adapting to changing raw material characteristics, it can automatically complete thickness adjustment and side roll gap adjustment accurately and at high speed, significantly reducing labor investment and effectively improving production efficiency.

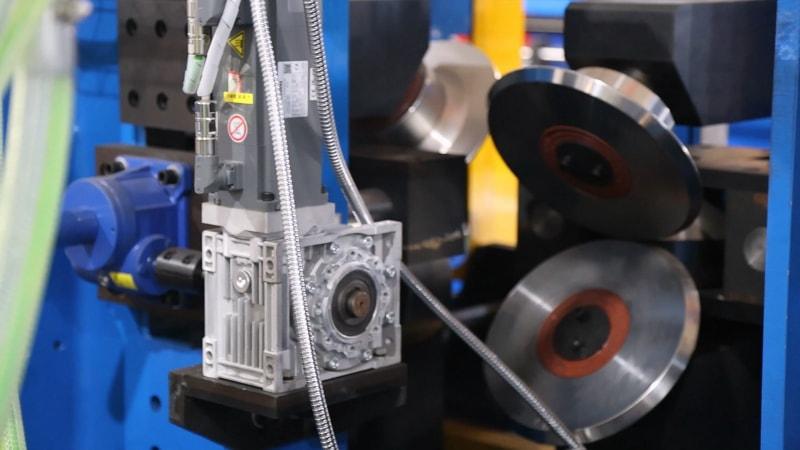

2). Fine equipment structure and drive system

- Diversified and strong dynamic support

Multiple motors are rationally arranged inside the equipment. These motors have a clear division of labor and work together to provide solid power guarantee for C-type conversion, thickness adjustment and roll gap adjustment. Each key link has adapted motor assistance to ensure stable and high-speed operation of the equipment. - Intelligent central control

The control cabinet is like the brain of the equipment. It is equipped with Siemens main drive inverter and servo motor drivers on the front and rear sides, which work in perfect harmony. They are like rigorous dispatchers, accurately controlling key parameters such as motor speed and steering according to preset instructions to ensure that the entire production process is orderly. - Accurate adjustment everywhere

It is worth mentioning that a servo motor is placed on each row of shafts and each roller. In automatic mode, these servo motors are like the hands of a delicate craftsman, completing various adjustment tasks with precision and accuracy, allowing each production process to reach standard precision.

3). Flexible thickness and roll gap adjustment

- Convenient and carefree control experience

Customers can select different thicknesses such as 2.5 mm, 3.0 mm or 3.5 mm with one click through simple operations on the device screen. The equipment receives instructions immediately, quickly and automatically starts the adjustment process, quickly and accurately adapts to the required thickness, and significantly shortens production preparation time. - Accurate adaptation of servo assist

The servo motor plays a key role in the roll gap adjustment process. With its high-precision control performance, the side rolling gap can be flexibly adjusted in real time according to different thickness requirements to ensure that the steel is evenly stressed during the rolling process and ensures excellent forming quality. - Carefully crafted to achieve quality appearance

The accurate adjustment of the vertical rolling gap and side rolling gap of the molding machine is not only focused on production efficiency, but also the persistent pursuit of product appearance quality. Through fine control, the R-angle of the steel is ensured to be regular and uniform, making the finished steel profile smooth in appearance and with clean lines, making it very competitive in the market.

The birth of the fully automatic CZ profile steel all-in-one machine marks that profile steel production has entered a new stage of high-speed intelligence. It will help many companies stand out in the fierce market competition, win development opportunities and write a more brilliant business chapter with their outstanding product quality and production efficiency.