Recently, we have successfully reached a cooperation with an end customer from Brazil. The customer decided to purchase three equipment at one time: PU composite panel forming machine, glazed tile forming machine and TR35 single-board forming machine. The completion of this order is not only a high recognition of our product quality, but also demonstrates our competitiveness in the international market.

This Brazilian customer conducted research on several forming machine suppliers in the early stage, and later chose to come to our factory for an on-site inspection. When the customer entered the factory, he showed great interest in the large scale of the factory, the high degree of modernization of the equipment, and the professionalism of the employees. They admitted that their previous impression of Made in China remained at the low-end production equipment, and our factory refreshed their cognition: spacious and orderly workshops, advanced processing equipment, and strict quality control, let them deeply feel the power of “professionalism” and “craftsmanship”.

During the visit, the customers were very interested in the equipment we produce, especially the humanization and practicality of the molding machine in design:

PU composite board molding machine can achieve fast and stable production, and the quality of the board is uniform and the surface is smooth, which fully meets the customer’s requirements for the performance of the finished product.

Glazed tile molding machine wins the favor of customers with its molding accuracy and durability. They believe that this equipment can help improve the market competitiveness of terminal products.

TR35 single board molding machine has won high praise from customers for its strong adaptability, convenient operation and stable operation.

Customers said that they have been looking for suppliers who can ensure the rapid operation of the production line, and our equipment is not only technically advanced, but also can provide long-term and stable support for production, fully meeting their requirements for equipment durability and reliability.

During the factory inspection, customers also felt our unique corporate culture and superior employee working environment. They believe that this tolerant and people-oriented atmosphere not only creates a good corporate image, but is also an important foundation for manufacturing products. They praised our team’s fast communication and professional service, and believed that this service attitude is a crucial factor in international cooperation.

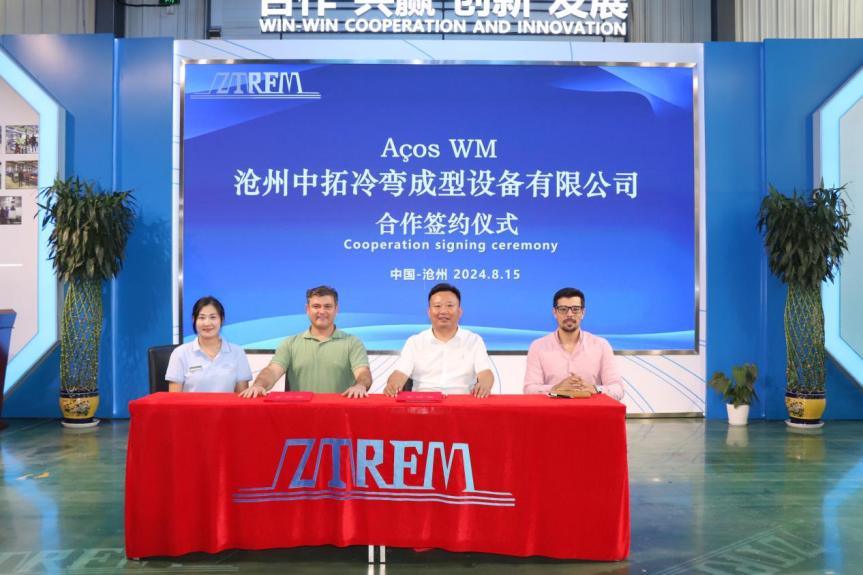

Through meticulous product display and in-depth communication, the customer decided to purchase these three equipment on the spot and made it clear that they would further deepen cooperation in the future. They believe that by cooperating with companies like us, they can not only obtain high-quality equipment, but also ensure long-term after-sales support and technical services, providing strong guarantees for their market expansion.

This cooperation with Brazilian customers fully demonstrates the competitiveness and reliability of our products in the international market. This is not only a reflection of our technical strength, but also a recognition of our corporate culture and service concept. In the future, we will continue to uphold the principle of “product quality, service first” to provide more high-quality molding equipment to global customers and help them achieve greater business success.

Through this cooperation, we have not only further consolidated our brand position in the international market, but also set a good example for expanding more overseas customers. We believe that with our technical strength and service experience, our equipment will become a partner for more international customers.