Colored stone-coated steel roofing tiles, also known as metal roofing tiles or stone-coated steel roofing, are an innovative and durable roofing solution. The tiles are made from high-quality galvanized steel and covered with a layer of stone particles, giving them the aesthetics of traditional clay tiles, slate tiles or asphalt tiles, while offering greater weather resistance and long service life. .

The main advantages of the colored stone tile production line:

- Durability: It can effectively resist heavy rain, strong wind, hail and other weather conditions.

- Fire resistance: non-flammable, especially suitable for areas with high fire risk.

- Energy saving: Its excellent reflective properties can significantly reduce heat absorption and improve building energy efficiency.

- Low maintenance cost: It has excellent properties of resisting cracking, fading and insect damage.

- Aesthetics: A variety of colors and design styles are available to meet different architectural needs.

- Environmental protection: It can be recycled and can be installed directly on the existing roof to reduce waste.

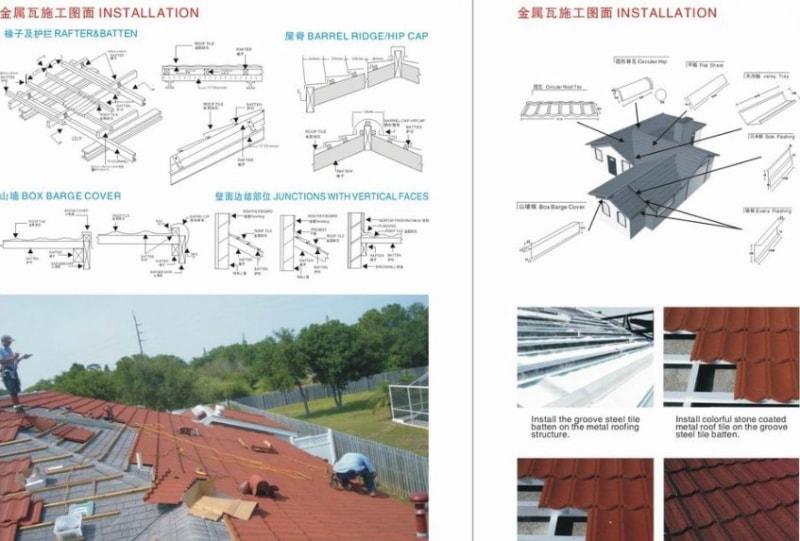

- Easy to install: The tiles are light in weight and easy to install, reducing construction costs and structural burdens.

- Long-term durability: These roofing tiles are a stylish and energy-efficient roofing option that will last for a long time.

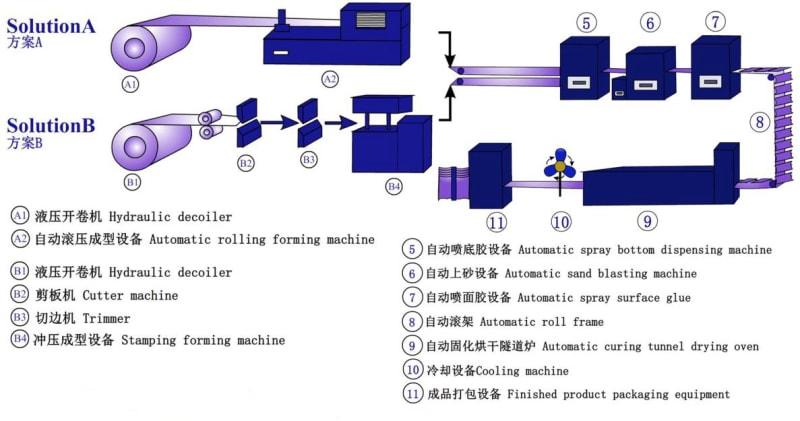

The production process of colored stone tiles:

Manufacturing colored stone-coated steel roofing tiles involves multiple production steps to ensure the tiles’ durability, weather resistance and aesthetics. Here is an overview of the production process:

- Steel base preparation

Steel selection: Use galvanized steel as the base material. The galvanized layer can effectively prevent steel from rusting and corroding.

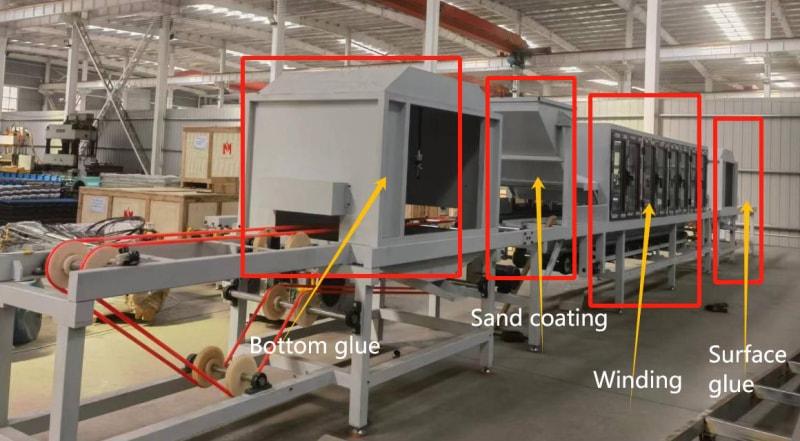

Cutting: Using cutting technology, the steel plate is processed into the required tile size and shape. - Apply adhesive

Adhesive layer: Apply a layer of adhesive on the surface of the steel tile to provide a good foundation for the adhesion of stone particles. - Stone smearing

Particle application: Spread the stone particles evenly on the steel tiles coated with adhesive. Stone particles not only enhance the appearance of the shingle, but also enhance its durability and weather resistance.

Curing: Let the coating cure to ensure that the stone particles are firmly attached to the surface of the steel tile.

4.Acrylic coating application

Coat Application: Apply an acrylic coating to the stone grain to further consolidate the stone grain and provide additional weather protection.

Drying: Use heat to ensure the acrylic coating is completely dry.

5.Quality control

Inspection: Each tile is rigorously inspected for signs of loose stones, uneven coating or damage.

Packaging: After quality inspection, the tiles will be packed and ready for shipment or storage.

- Additional steps (optional)

Color Coatings: Color coatings can be optionally added on top of the acrylic layer for unique color effects.

Customization: Depending on customer needs, tiles can be customized in different shapes, sizes and finishes.

7.Storage and processing

Storage: Finished tiles should be stored in a dry, well-protected area to avoid damage prior to installation.

Installation treatment: Care must be taken during installation to avoid damage or stone peeling.

Summary: The colored stone-coated steel roof tile production line uses advanced manufacturing processes to produce roof tiles that are strong and durable and can withstand various environmental conditions. Not only are the products weather-resistant and aesthetically pleasing, they are easy to install and low-maintenance, making them suitable for a variety of construction projects and ideal for modern roofing solutions.