Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

Metal wall panel rolling forming machine

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

Metal wall panel rolling forming machine could be used for make the metal wall cladding panels in batch fully automatically.

Wall panel making machine also called wall cladding machine.Wall claddings are available in several types and forms – from normal wooden panels to 3D wall panels. Their types differ in material, texture and dimensions. Some of the common indoor wall cladding types is wood cladding, steel cladding, stone cladding, etc.

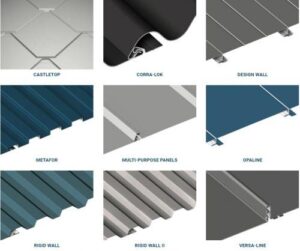

Type of Wall Claddings

Wall claddings are available in several types and forms – from normal wooden panels to 3D wall panels. Their types d

iffer in material, texture and dimensions. Some of the common indoor wall cladding types is wood cladding, steel cladding, stone cladding, etc.

Aluminum Cladding

Aluminum cladding is costly when compared with vinyl cladding units. But aluminum cladding guarantees more durability and longer life than the vinyl cladding. Same like the rolling forming machine, wall cladding rolling forming could be used to make either aluminum cladding panels and PPGI panels. These units are subjected to less maintenance or replacement over the years. Aluminum cladding is used mainly for basement and storage walls of the building. High quality and treated aluminum cladding are used for large commercial buildings and structures. Even if long time, it also keep fresh and new. Zhongtuo wall cladding panel machine can do all of then metal rolling forming works for you. Here are the machine pictures for your reference.

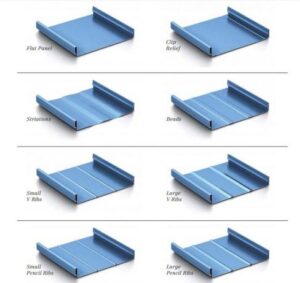

Metal wall cladding rolling forming machine ribs options:

No matter which type wall cladding panels rolling forming machines you choose, the ribs you can choose to add or not or choose which type and then it will give different wall cladding effect.

By adjusting the embossing rollers, any above ribs could be made by the wall cladding panel rolling forming machines.

Metal wall cladding rolling forming machine has the following features:

It has pre-cutting system which allows you to cut the sheet at any length.

With many type ribs options, by one machine you can make many types wall cladding panels.

Linear function. One machine can make any width wall cladding panels within some range.

All rollers are chromed for long time to use.

PLC control for width and size changing, fully automatic.

Wall cladding profiles offers unlimited design potential with its sleek, crisp appearance and attractive shadow lines. Eliminating the need for metal roof clips, the concealed 1″ self-locking Snap Lock system creates a powerfully protective seal. Versatile and refined, this easy-to-install metal roof delivers superior beauty, durability and strength while showcasing architectural details.

Concealed fastening metal wall and fascia panel rolling forming machine

Concealed fastening metal wall and fascia panel rolling forming machine is designed to produce concealed fastening metal wall and fascia panels in batch fully automatically. Concealed fastening metal wall and fascia panels provide the toughness of metal while creating an attractive, flexible and functional wall or fascia panel. The panel is offered in fluted and flat panels, which are equally effective for new construction or retrofitting existing buildings. If your design calls for a smooth or flat wall or fascia, this series 12.0 Flat Panel is good for you. Flat Panel offers a 1 ¾-inch deep leg providing the perfect cavity for rigid board insulation.

Machine elements

3 Ton manual decoiler, guiding rollers, pressing rib device, plate cutting and pressing device, rolling forming pressing rollers for the big edge, pressing shape and pressing molds, rolling forming and cutting device, receiving table, hydraulic station, PLC control system and others.

Machine design idea

The machine design, we use the linear system, the linear motor control the sizing changing.

The self-adjustable gusset machine is a single-roll forming unit that can produce a variety of width specifications. The machine is mainly composed of 3T passive loading frame, guiding device, 2-channel pinch roller, flat cutting device, forming host. , the discharge platform, hydraulic station, computer control cabinet, and other parts.

1, the upper shaft of the pinch device adopts the cylinder lifting, and the clamping force is automatically adjusted according to different thickness materials.

2, the whole machine is a chain-type chain transmission; the structure is firm and simple.

3, a machine can produce different waist height sizes. The specification change adopts the form of through-axis, which is fixed on one side, and the other side is automatically moved by the motor. Any fast and steeples change of width dimension, that is, the width can be changed in single digit size (such as 101, 102, 200. 250, etc.)

4, using the flat cutting process, no need to replace the cutting die when changing specifications

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.