Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

Professional manufacturers sell high-quality roof forming machines roof sheet making machine、sheet metal forming

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

Zhongtuo cold rolling forming machine factory has the rolling machine deign experience of more than 10 years. For the metal roofing sheet sheets machine, we have the following popular designs like, IBR metal roofing sheet machines, corrugated board rolling forming machines, step tile rolling machines, glazed tiles rolling machines, sandwich panel panel rolling machines and others.

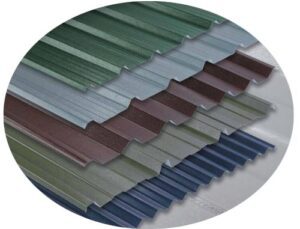

The finished products, color steel roofing sheets are suitable for industrial and civil buildings, warehouses, special buildings, roofs, walls and interior and exterior wall decorations of large-span steel structure houses. It has light weight, high strength, rich color, convenient and quick construction, earthquake resistance, fire protection, rain protection, and longevity. Long, maintenance-free and other characteristics have been widely promoted and applied.

We have Roofing Sheet Making Machine.Metal roof sheets are an affordable option, able to withstand high temperatures for this purpose, ZTRFM roofing former offer to you Roofing Sheet Making Machine and Roof Panel Roll Forming Machine. It is the best reliable and affordable roofing system in the marketplace in a range of designs and styles

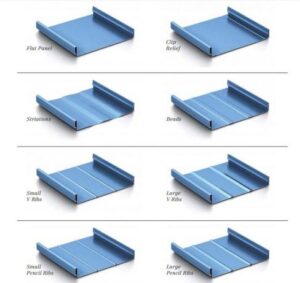

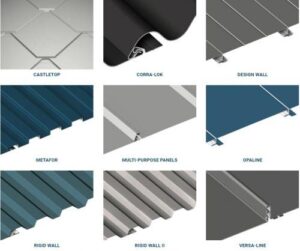

Therefore, the ZTRFM group customizes various types roofing sheets and wall panels to you.you can see the following videos and know all of the roof tile panel and wall tile panel including:

Popular design of R panel profile

Max ribs panel profile

TUFF-RIB PANEL profile

Box Rib PANEL profile.

AG metal PANEL profile.

Corrugated PANEL profile

STANDING SEAM METAL ROOFS profile

Batten style panel profile

GLAZED TILE profile

Q tile machines and others.

Machine elements and each part detail introduction:

Actually most of roofing tile rolling forming machines is composed by the following elements:

Decoiler: we have both Manual type or hydraulic types of 5 ton, 7 ton 10ton or others.

Main rolling forming machine: the roller station and detail elements will be designed according to customer requirements and drawing profiles;

Receiving table, we have manual one and the fully aromatic stacker.

How to design proper metal roofing sheets machines?

For all metal roofing sheet machines we customize according to customer requirements. First we need the customer drawing profile and then we can give the proper design plan.

Step 1: get profile:

Get the drawing profile and then give customer proper feedback. Take the following drawing profile for example:

By the drawing profile can just that this drawing profiles is from north American and then we need to confirm with the customer input coil width and the material hardness. Different material and then the machine design will be different. Then we will give accurate drawing profile input coil width and then confirm with clients. Meanwhile recommend other popular designs in American for customers to choose.

Step 2: Design Machine according to customer requirements:

For example, if the customer have speed requirements, we have options high speed gearbox type metal roofing sheet machine. If the customer have durability requirements, we have molding frame strong version metal roofing sheet machine to recommend.

Step 3: Confirm order and arrange the production:

When finalize the order, we will stamp and sign the contract and quotation and then send to customer. Once we get the deposit from clients then arrange the production. Bur before we arrange the production, we will give the 3D or CAD file of machine layout and design then confirm with clients, like machine color, electricity and others.

Step 4 Testing and arrange the delivery of the metal roofing sheet machine.

Different with other factory, ZTRFM metal roofing sheet machine testing we use the coil not the single sheet. Normally speaking, by single sheet testing we can not find the big problem when rolling, like the measure length is not accurate, the sheet will go swing or others. In a word, we test the machines seriously like the customer is here. Meanwhile we have 12 webcams in our factory, you can check the machine testing by webcam at any time.

For more roofing sheet designs ZTRFM has more options for your reference:

metal roofing machine

Elevate your construction game with the precision and reliability of Metal Roofing Machine, your go-to solution for flawless metal roofing. Designed to meet the demands of modern building projects, our Metal Roofing Machine guarantees durability and aesthetic appeal. Perfect for commercial or residential applications, it streamlines the installation process, saving you time and resources. Trust in Metal Roofing Machine technology to deliver professional results that stand the test of time. Upgrade today and ensure every project is crowned with quality and efficiency, courtesy of Metal Roofing Machine expertise.

roof sheet making machine

Transform your roofing projects with unmatched efficiency using the Roof Sheet Making Machine, the industry’s leading solution for high-quality roof sheet production. Our Roof Sheet Making Machine is engineered to perfection, ensuring sheets that are both durable and weather-resistant. Ideal for contractors and manufacturers seeking superior output, this machine guarantees consistent performance and ease of use. Experience the difference in productivity and craftsmanship by integrating a Roof Sheet Making Machine into your operations. With our Roof Sheet Making Machine, you’re not just building roofs; you’re crafting lasting impressions that define excellence in construction.

roofing sheet crimping machine

Elevate your roofing projects to new heights with the advanced technology of our Roofing Sheet Crimping Machine. Designed for precision and durability, our Roofing Sheet Crimping Machine ensures flawless crimped edges on every sheet, enhancing both strength and aesthetics. Perfect for professionals demanding top-tier results, this machine streamlines the roofing process, making complex installations straightforward. Whether you’re tackling residential or commercial builds, rely on our Roofing Sheet Crimping Machine for consistent, high-quality output. Experience the difference in efficiency and reliability that our Roofing Sheet Crimping Machine brings to every job site.

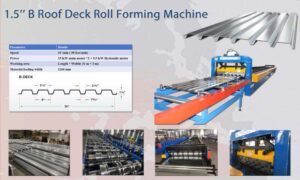

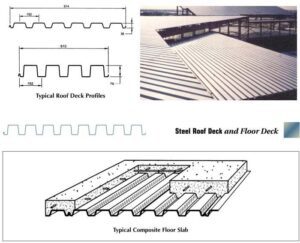

floor deck roll forming machine

Unleash the potential of your construction projects with the Floor Deck Roll Forming Machine, a versatile tool designed for the creation of steel floor decks. This machine is indispensable in the building industry, particularly in multi-story constructions, bridges, and industrial facilities, where its ability to produce strong, lightweight, and fire-resistant floor decks is crucial. The Floor Deck Roll Forming Machine transforms flat metal sheets into corrugated profiles, enhancing structural integrity while facilitating quick installation. By integrating a Floor Deck Roll Forming Machine into your operations, you can significantly reduce construction timelines and material costs. Its application in various sectors, from commercial complexes to residential developments, showcases its adaptability and efficiency in meeting diverse architectural requirements. Embrace the future of construction with the Floor Deck Roll Forming Machine, where innovation meets practicality.

Here are some popular drawing profiles for your reference,

please check flipbook to choose the proper drawing and then we can make the accurate quotation.

Roofing sheet with felt of PE form or anti-condensation material.

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.