Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

Glazed Roof Sheet Machine

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

Glazed Roofing Sheet Press Machine

Glazed Roofing Sheet Press Machine is designed to produced the metal step tiles or glaze tiles, which are widely used to produce mainly metal roofing and wall cladding sheets, and the most popular metal sheet roll forming machines in the markets can be found here. Our roofing sheet roll forming machine have muti-function, not only can produce normal PPGI and color steel material,also can use for composite material.

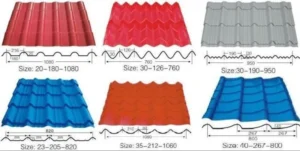

Take the following drawing profile for example:

The finished product of Glazed Steel Tile Making Machinery For Colored Glazed Steel Roofing Sheet is widely used in the construction of various industrial plants, villages, warehouses, supermarkets, hotels, exhibition, family construction, shopping malls shutter doors and etc. It has the advantage of beautiful, classical appearance.

Some Details of The Machine:

Feeding Part

The feeding rollers which we use is stainless steel.

And the ball bearing roller is inside the feeding rollers which is very convenient to feed the steel coil into it.

Main Roll Forming System

Feature: Ensure stability , precision and lifetime.

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission, roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.