Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

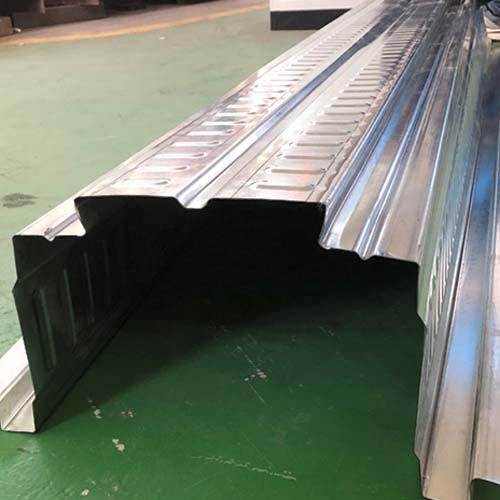

Trapezoidal steel decking single wave rolling forming machine for Jordan

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

Trapezoidal steel decking single wave rolling forming machine for Jordan

Trapezoidal steel decking single wave rolling forming machine for Jordan is designed for one Jordan customer which can be used for making trapezoidal steel decking single wave in batch fully automatically. MD225 decking is the most advance trapezoidal steel decking product on the market and is a direct alternative to precast concrete planks, delivering unpropped span capabilities of up to 6.0m It is a long spanning metal decking panel installed on the top flange of the steelwork. It also can be designed compositely to two waves types and by lowering down the wave height. Here I will share some drawing profiles for your reference:

Single wave:

Two wave types:

Trapezoidal steel decking single wave rolling forming machine for Jordan design:

Here are some Trapezoidal steel decking single wave rolling forming machine for Jordan parameters for your reference:

|

Roll forming machine |

Feeding&Guiding device | Leveling part with the hydraulic shearing, automatically PLC control | |

| Rolling shaft material | 45# STEEL | ||

| Shaft diameter | 90mm | ||

| Roller material | 45# steel | ||

| Rolling station | 32 stations | ||

| Work speed | 15 to 20 m/min | ||

| Machine structure | Middle plate welded frame | ||

| Machine basic frame | 500# H steel welded | ||

| Bearing | Roller bearing | Famous brand of Harbin | |

| Work power | 15 kw | ||

| Transmission | By Chains | With cover | |

Trapezoidal steel decking single wave rolling forming machine for Jordan

- Zhongtuo metal decking machinecan produce a variety of specifications of the floor bearing plate, can also be customized according to the customer’s requests, to meet the needs of all customers.

- Machine working speed canpossess the production speed of up to 25 m/min.

- Modular design and manufacturing. parts universal rate are high, simple maintenance.

- The enhanced design of the mainframe structure and quality control allows our metal rolling equipment to produce thicker plates for you.

- AII the processing of the frame is completed at one time, and the advanced machine tools ensure the accuracy of the size and position of each fit so that our molding unit almost does not need repeateddebugging, with very little dependence on personnel.

- The automatic program control technology is adopted. The parameter setting of the metal deck roll forming machine is simple and convenient, and the degree of automation is high. The system’s self-learning ability is strong, and the control system uses the high-quality brand. In addition, the man-machine interaction interface is also very user-friendly.

- For the special design of the shaft and embossing rollers, it can make sure the metal profile has good overlapping effect and good profile shape size.

Trapezoidal steel decking single wave application:

Get a quote

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 250+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.