Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

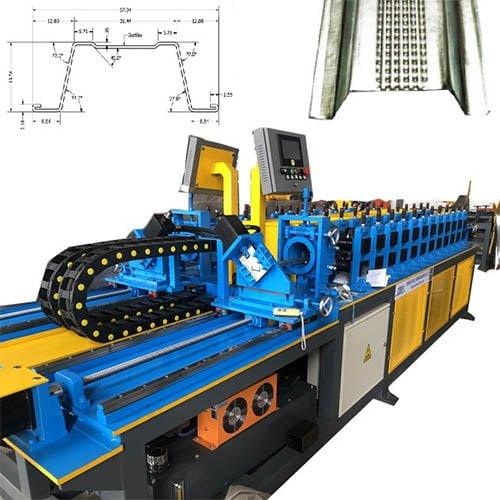

Combo hat profile and wall angle profile rolling machine

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

Combo hat profile and wall angle profile rolling machine

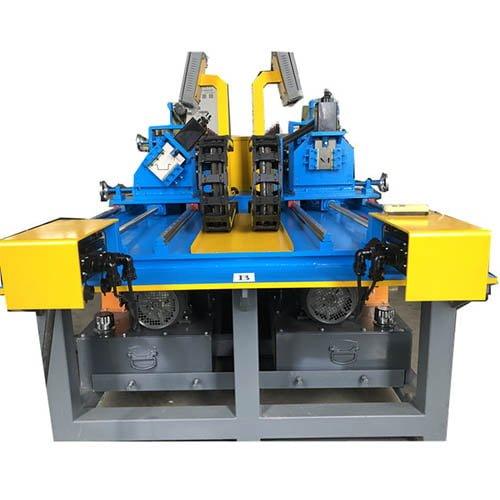

Combo hat profile and wall angle profile rolling machine is a kind of combination of two profiles by one machine. This type rolling forming machine could be used to make two profiles by one machine at the same time.

Combo profile rolling machine advantages:

- Two profiles could be made by one machine

- Two lines could work at the same time.

- Working speed can reach 45 meter per minute.

- It takes less space and less worker. One worker can watch two production line.

Here we take one example for your reference:

Combo hat profile and wall angle profile rolling machine

Misunderstanding about Combo profile rolling machine:

- COMBO is not cheaper than two machines as the base frame more bigger ,all motors, PLC hydraulic system are two sets, so no elements saved.

- It is different like two roller with one shaft.

- It is more durable and long time to use.

Combo hat profile and wall angle profile rolling machine parameters for your reference:

Main Machine:

Size: 4800х1800х1400Weight t: 3.2tons

Voltage:380V/50HZ3Phase(as customer’s request)

Roller fixer : Guide column

Frame : middle plate welded

Memorial arch frame type

Frame thickness:25mm

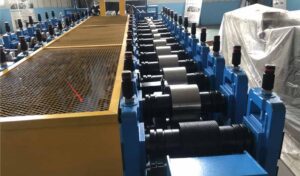

Drive mode: gear

Material of rollers: GCr12MoV

Material of shafts: 40Cr steel with tempering

Diameter of shafts: φ60mm

Number of rollers for C stud :16 rollers

Number of rollers for U channel :14 rollers

Main power: 5.5 kw for each part

Cycloidal planetary gear speed reducer

Punching H holes

This part will help you press your company logo on the finished products.

Power: hydraulic

Note, if you need to punch logos, please tell me in advance this price does not include.

Servo tracking shearing system

Material of blades: Gcr12 quenched

Power supply : hydraulic power

Frame : Pillar style with rack & pinion system

Stroke switch : non-contact photoelectric switch

Punching holes

The hydraulic station to punch holes, one station.

The molds are changeable. We will give related holes molds.

We put the hydraulic station with the machine, all the hydraulic pipe connected well.

We add the oiling system with the machine. As when you use the GI coil, and working high speed, the zine coating layer will be on the surface of rollers. By the oil adding, there will no such problem happened.

As to the design, not all profiles could be designed like this, some wide coil can not be designed like this. But the narrow strip coil could be designed like this.

With the protection cover, when machine working, it is more safe.

When you need to design such machine, please show me your drawing profile and then we can try to design machine for you.

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.