Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

Rolling shutters forming machine of galvanized steel profiles with flat or curved cross section (solid)

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

Galvanized steel Rolling shutters forming machine with flat or curved cross section (solid)

Rolling shutters forming machine of galvanized steel profiles with flat or curved cross section (solid) is professionally designed for producing rolling shutters in various types. First let us check how many types rolling shutter has:

Rolling shutter of L110 with punching and without punching, with lock hole and without holes:

The L110 rolling shutter is of galvanized steel profiles with flat cross section. It is made of galvanized steel with thickness from 0.6mm to 1.2mm, depending on your needs.

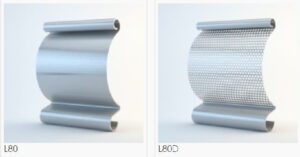

L80 is different with L110, it is curved but we can design it either with punching and without.

the L80 rolling shutter of galvanized steel profiles with curved cross section is made of galvanized steel (thickness 0.6mm up to 1.0mm depending on your needs). It has optimized cross section and reinforcements at key points for improved durability and reliability, even when fitted in extremely wide openings and regions with high wind pressure. The profile of the rolling shutter that touches the ground is extensively reinforced and consolidated so that it delivers the highest levels of security. The product is further provided with a sealing rubber band that ensures the outmost adaptability and tightness of the roller shutter to your space.

High Speed Rolling shutters forming machine designs:

High Speed Rolling shutters forming machine designs Features:

- It supports hot dip galvanizedsteel, GI and other material.

- It can make the contemporary look, wavy appearance

- Support the material thickness: 0,6 mm, 0,8 mm, 1,0 mm and under special requirement 1, 2 mm

- The shutters could be heavy and very rigid.

- The high speed can reach 35 meter per minute.

- Use the molding frame of 35mm, for long time to use.

- Use the servo flying tracking cutting saw to get the higher speed.

- Add the cooling system.

- With the oiling system to protect the coil and rollers.

- Rolling shutters forming machine of galvanized steel profiles with flat or curved cross section (solid), daily used in life.

How to get the accurate quotation?

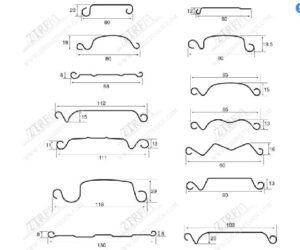

For making the quotation fast and accurate of rolling shutters, please supply the drawing profile like this and then we can the quotation for you at once.

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.