Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

Plank decking scaffold boards rolling forming machine

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

Plank decking scaffold boards rolling forming machine

Plank decking scaffold boards rolling forming machine is designed to make the scaffold boards or plank decking in batch fully automatically. Plank decking scaffold boards is considered more durable than timber giving it a longer lifespan and is also fire retardant. It is strong and sturdy providing a safe and steady platform to work form being able to withstand heavy load pressure that scaffolding must undergo with workers and equipment working at height. Here we take some drawing profiles for your reference.

Normal speaking the parameters will be like this:

Supported coil width: ≤500 mm Material thickness: 1.0~2 mm

Supported material: carbon steel Machine working speed: 6~10 m/min

Plank decking scaffold boards rolling forming machine

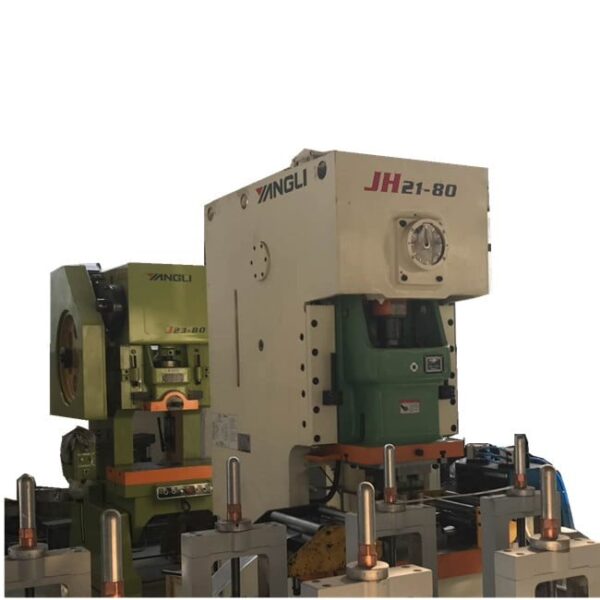

Plank decking scaffold boards rolling forming machine is composed by the following elements:

The price is included one hydrualic decoiler 5 Ton, one pressing machine, two sets of punching molds, servo coil feeder, main rolling forming machine, shearing system, hydraulic system, PLC control panel and runou table.

Decoilerà levelingà servo coil feedingà punching systemà roll forming machineà sizing and shearing

Systemà runout table

As to all the elements, we can customize according to your requirements like decoiler, you can choose manual one or hydraulic one, the punching machine machine, you can choose world famous brand one or normal one. Also for the main rolling forming machine, gearbox type and the chain type, cost will be big difference. So if more clear requirements and then the quotation will be more accurate.

Testing and quality control:

For the all accuracy could be controlled within 0.0.5mm.

If you want to make two sizes or more by one machine, how to adjust rollers.

Not all the sizes could be made by one machine, we need to check whether those sizes are adjustable or not. By adjusting the spacers and cutting blades and then you can try to make more than one size by one machine.

Get a quote

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 250+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.