Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

400-1500mm wide orange peel pattern color steel aluminum coil embossing machine metal sheet embossing machine

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

Orange peel pattern color steel aluminum coil embossing machine

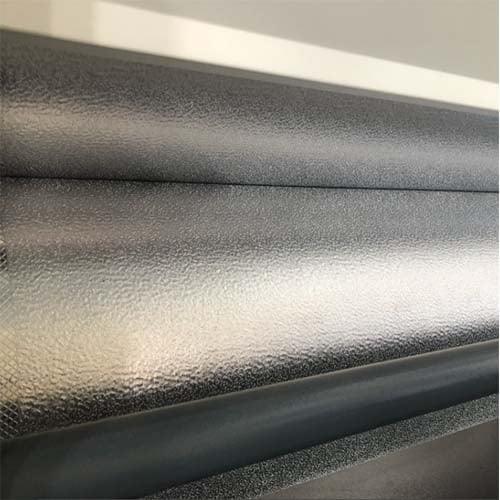

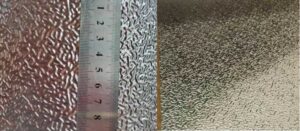

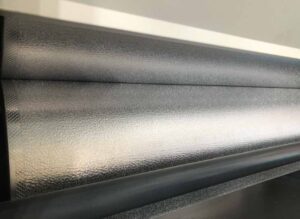

400-1500mm wide orange peel pattern color steel aluminum coil embossing machine metal sheet embossing machine is designed to make the metal embossing sheets in batch fully automatically. The material could be like color steel PPGI, could be aluminum, stainless steel or others. Mostly it works for decoration and some times for automobile exhaust pipe insulation board. Here are some samples of embossing types for your reference;

400-1500mm wide orange peel pattern color steel aluminum coil embossing machine metal sheet embossing machine

The width is adjustable. For this machine, we have some options for your reference:

Option A: Use the coil and then from coil to embossing and then recoiler.

Option B: Use the plate, only embossing and supporting table.

Option C: Use the coil and then from coil to embossing and then cut to length.

Embossing machine parameters for your reference :

- Embossing roller material: 42crmo solid forged alloy steel

- The thickness of the pressed material: 1mm

- Width of pressed material: within 1200mm

- Speed: 0-8m/min

- Pattern: water ripple

- Material to be pressed: carbon steel coil

- Pattern depth: 0.5-2cm, pattern depth is adjustable

- Embossing roll specifications: ø410*1600mm. The width of the pressed material finished product is less than or equal to 1500mm;

- Roll structure: integral forging;

- Roll heat treatment: medium frequency quenching of the roll body;

- Roll hardness: ≦HRC55;

- Roll pattern: According to drawing requirements: CNC engraving;

- Flower roller surface: anti-rust treatment (self-spraying chrome paint)

- Rolling mill stand; steel plate combined structure

- Rolling mill drive; adopts frequency conversion speed regulation

- Embossing method; two rolls of concave and convex opposing pressure

- Pressure adjustment method: reducer pressure adjustment (upper embossing roller and lower embossing roller matching gear adjustment function)

- Center height (between the ground and the two rollers): 750mm

- Electric control part; independent control cabinet

- The gap between the rolls can be adjusted

- Flower roller: detachable to change the roller.

- Cycloidal pinwheel reducer: XWD8-15

- Frequency conversion motor power: 15KW/380V(50Hz) 3 phases, (voltage optional)

- Inverter brand: Delta

- Three-phase asynchronous motor: Nanjing Shunbai Motor Co., Ltd

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.