Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

Metal tile 3D model metal roofing sheet rolling forming machine

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc.

Title: Metal tile 3D model metal roofing sheet rolling forming machine

Keywords: metal tile machine, metal roofing sheet machine, rolling forming machine

Description: Metal tile 3D model metal roofing sheet rolling forming machine is designed to make the metal roofing tiles in batch fully automatically.

Metal tile 3D model metal roofing sheet rolling forming machine

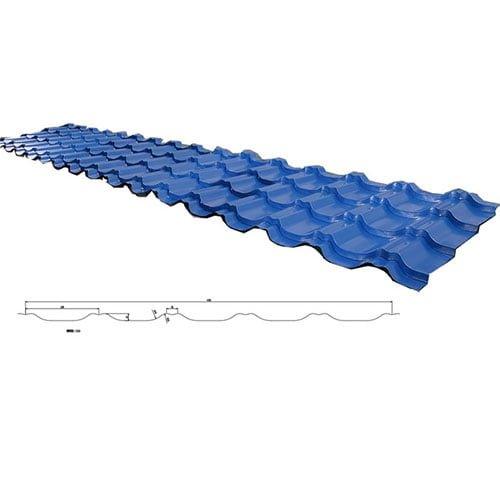

Metal tile 3D model metal roofing sheet rolling forming machine is designed to make the metal roofing tiles in batch fully automatically. The normal machinable thickness range of our roof panel roll forming machine is 0.3mm-0.5mm, the standard or more used in international market is Gauge 26 (0.45-0.5mm), working raw material is Aluminum, PPGI, Galvanized steel, Galvalume steel etc. Normally for the 3D model metal roofing sheet, the more smaller in range and the more beautiful in the profile shape.

Take the following drawing profile for your reference:

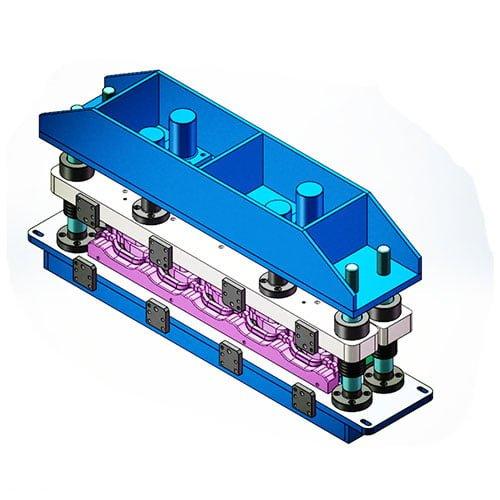

Compared with the 3D mode metal roofing tiles and the normal step tile, the most big difference lie in the shearing system.

It includes a cutter holder, the upper part of the cutter holder with an oil cylinder,

With an upper knife beam, upper cutting knife is fixedly installed on the upper knife beam through the

connecting plate, and the lower cutting knife is arranged corresponding to upper cutting knife.

The lower cutting knife is fixedly installed on the lower knife beam, and the lower knife beam is arranged on the cutting knife frame.

| Guiding device | Placed on the machine by seller |

| Rolling shaft material | 45# STEEL |

| Shaft diameter | 75mm |

| Roller material | 45# STEEL |

| Rolling station | 18 stations |

| Work speed | 7-8m/min |

| Machine basic frame | Steel plate welded |

| Machine body | 400# H steel welded |

| Bearing | Chinese famous brand Harbin |

| Work power | 7.5kw servo motor |

| Transmission | By Chains or gearbox |

| Safety cover | Available |

Get a quote

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 250+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.