Technologicaly Changes & Industrial Systems, We Are Dedicated To

Provides Seds The Best & Economical Solutions To Valued Customers.

Steel Slotted Strut Channel Rolling Forming Machine

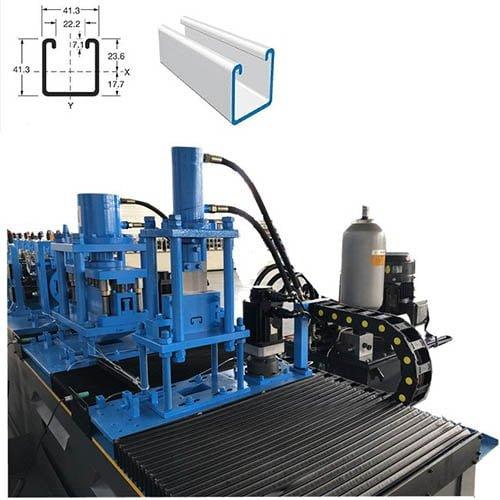

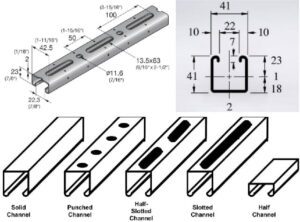

different types of cold roll forming machines. We are a factory with a long history, engaged in the design and manufacture of roll forming machines since 2006. The machines we can produce include: roof tile making machine, cz purlin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high frequency pipe welding machine, slitting line, cut to length line, shelf system forming Machine, floor decking forming machine, color stone tile production line, hot laminating filmed machine,etc. Steel Slotted Strut Channel Rolling Forming Machine is designed for making strut channels in batch fully automatically. Standard structural component generally used for the support of electrical or plumbing products (such as cable tray/ladder, lighting rigs, or pipe clamps), but it also has a wide range of other uses for installing just about anything.41mm slotted channel with punched holes. Galvanized steel for typical outdoor environments. Here is the one drawing profile for your reference

Keywords: strut channel machine, rolling forming machine, slotted strut channel machine

Description: Steel Slotted Strut Channel Rolling Forming Machine is designed for making strut channels in batch fully automatically.

Steel Slotted Strut Channel Rolling Forming Machine

Steel Slotted Strut Channel Rolling Forming Machine is designed for making strut channels in batch fully automatically. Standard structural component generally used for the support of electrical or plumbing products (such as cable tray/ladder, lighting rigs, or pipe clamps), but it also has a wide range of other uses for installing just about anything.41mm slotted channel with punched holes. Galvanized steel for typical outdoor environments. Here is the one drawing profile for your reference:

If you need to add the zigzag, we can also add also:

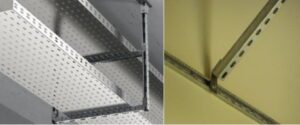

Here are some usage of strut channel:

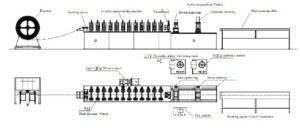

Working flow of strut channel rolling forming machine:

Different the traditional design, this one we use the after punching by servo motor like the following flow.

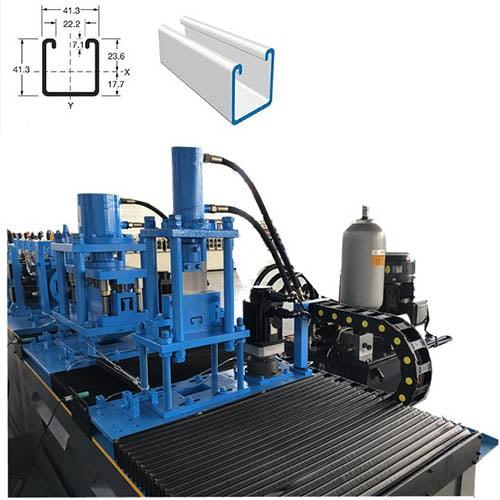

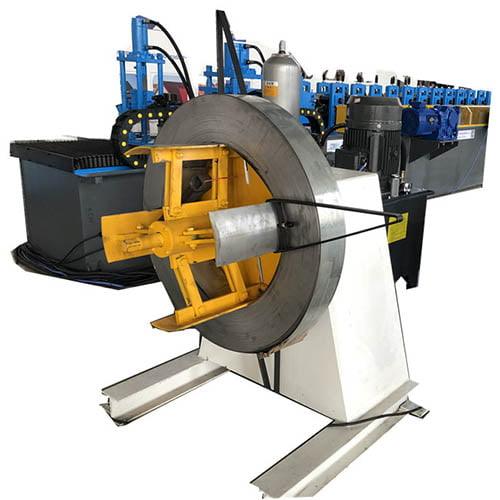

It is composed by the following elements: 3 Ton deoiler, main rolling forming machine with servo punching online and shearing system and the receiving table.

Advantages of light duty strut channel rolling forming machine:

- The decoiler you can choose hydraulic automatic type or manual one. Even if you choose the manual one, our decoiler with protection arm for coil peel off and brake for safety.

- The main rolling forming machine, we use molding frame for longtime to use and strong connection.

- Rolling part with two turkey heads, one is with the tape rollers to make the side straight. And the second one is for the straightness in the length.

- For punching part, we use the online punching by servo motor. Each time it can punch 10 holes and each minute can punch 40 times so the speed can reach 20 meter per minute.

Why choose us?

OEM/ODM & Customization one-stop service

Full after-sales service support

Provide OEM、ODM

2.Technician design:make drawing profiles and 3D machines drawing

3.determine the configuration and production

4.testing before delivery

6.Technical guidance

7.After-sales service:Installation services for complex machines and regular customer visit

Trusted By 95800+ Companies

high-quality enterprises. Through cooperation with us, they have received

strong support and achieved business breakthroughs and development.